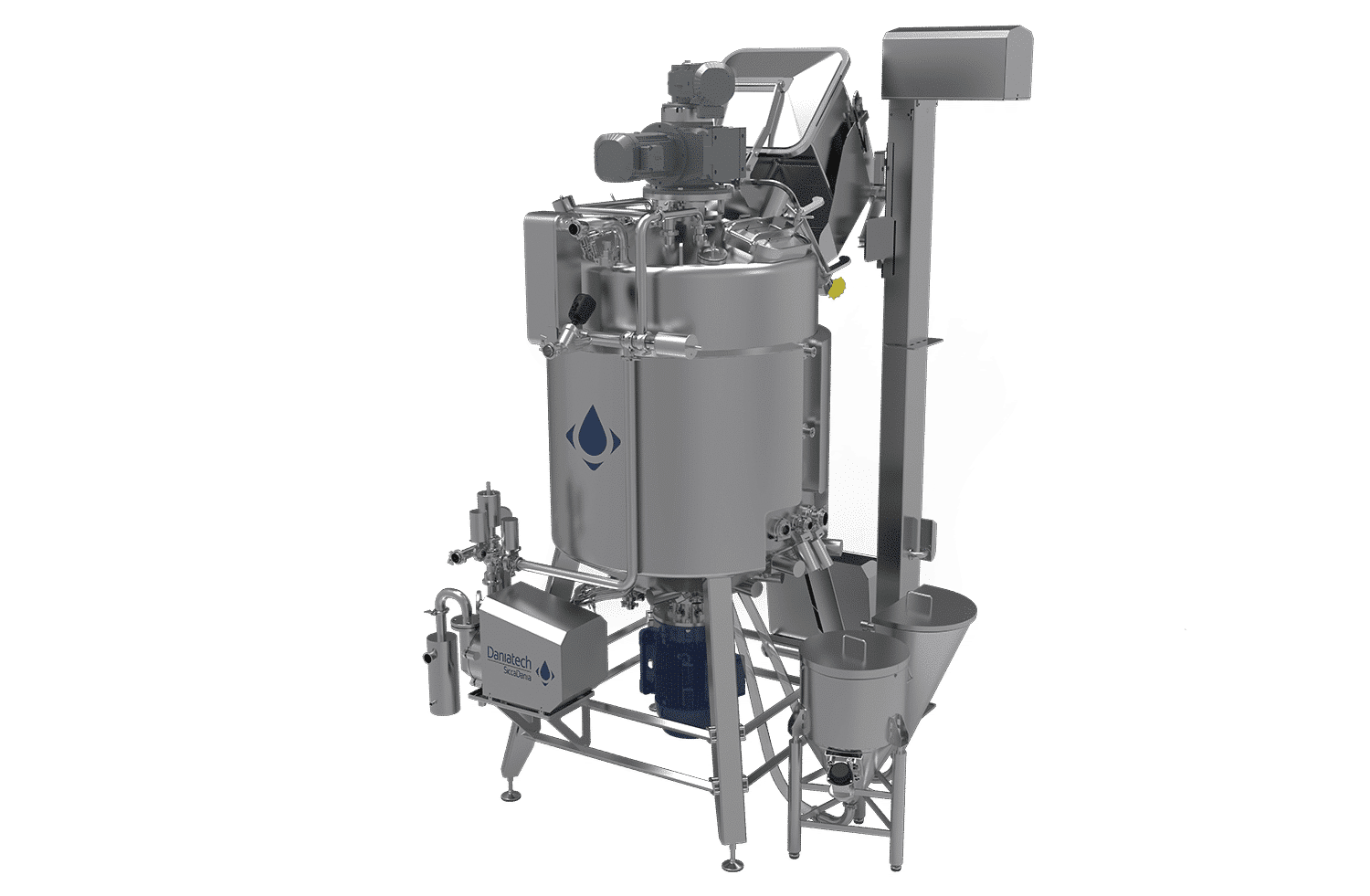

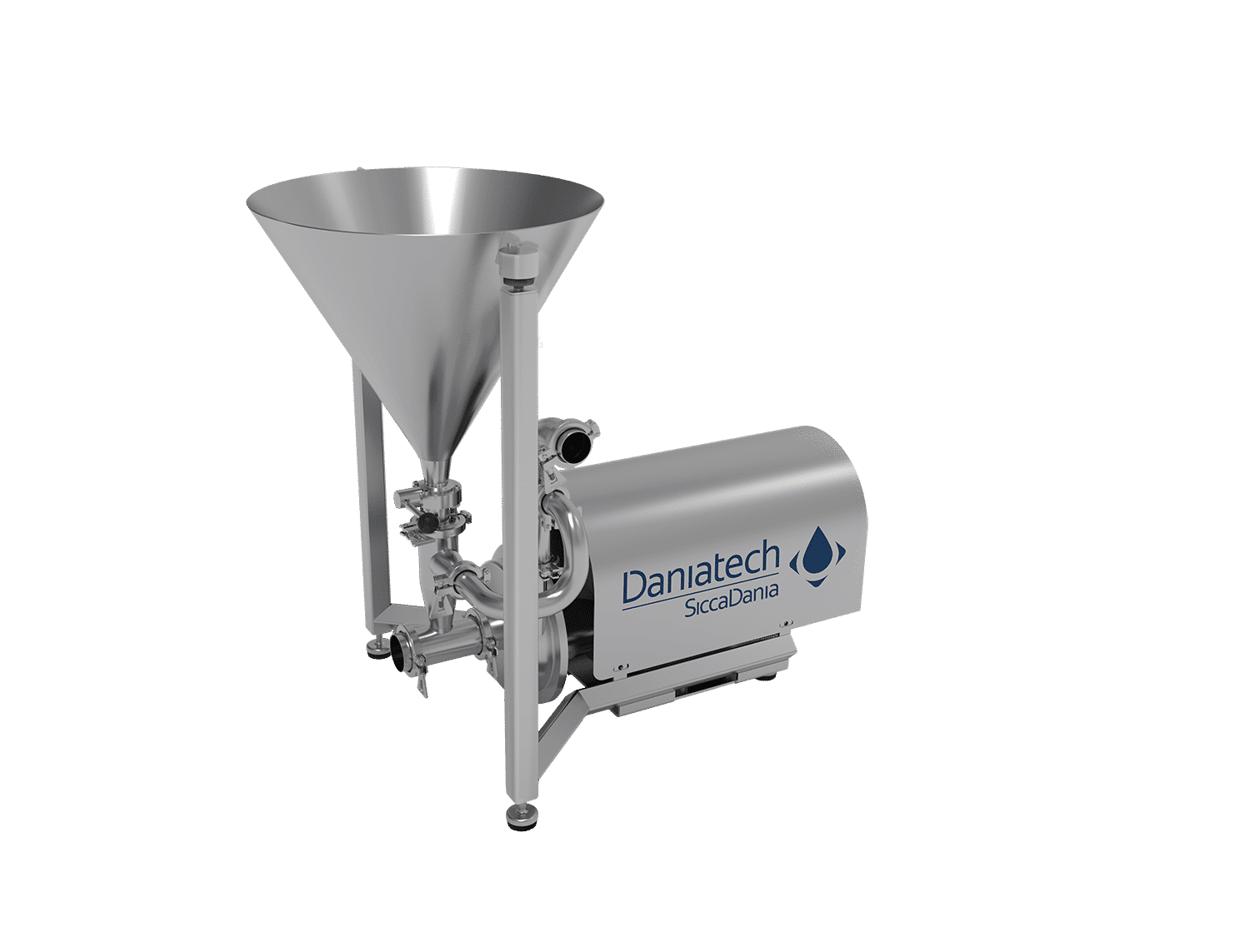

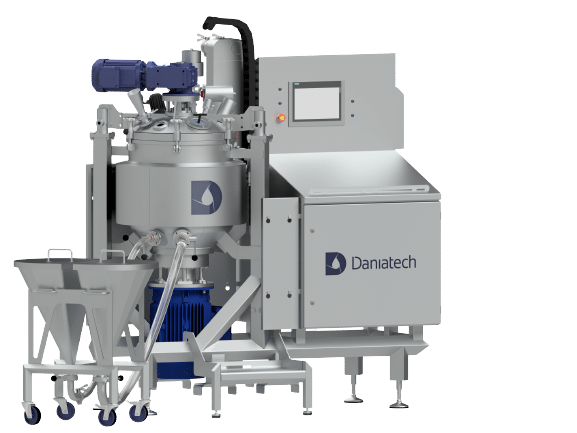

The ProcessMaster uses a vacuum to draw the powder from the funnel into the mixer below the liquid level where the powder is instantly wetted. The powerful, high-shear mixer and scraper agitator generates a controlled vortex in the tank. The combination of vortex and vacuum effectively separates air from the liquid and generates a perfect homogeneous dispersion within seconds.

The unit comes with an insulated jacket for quick heating and cooling with steam or ice water. For extra quick heating, the unit can be equipped with direct steam valves.

The result is a highly stable and homogeneous, air and lump-free product.

The ProcessMaster is uniquely compact and perfectly optimised for energy-efficient high shear mixing, while also saving our customers on maintenance costs.

Process overview – The ProcessMaster operating as a batch mixer

Applications

The mixer is used for mixing of:

- Sauce

- Mayonnaise

- Dressing

- Gels

- Cream

- Emulsion

- Etc.

Homogenisation down to 3µ lump-free and viscosity up to 50.000 cP.

Standard Equipment

- Mixer unit with flushed mechanical shaft seal (requires frequency control)

- Vacuum pump with a water-saving unit (requires frequency control)

- 3-way valve for CIP of vacuum pipe

- Insulated Steam/cooling jacket flange connection

- Scraper agitator

- Double agitator

- Manway with safety sensor

- Inspection glass with wiper/inspection glass with an LED light source

- 2 x powder valves (butterfly)

- 1 x outlet valve (butterfly)

- 2 x rotating spray balls with a 3-way valve from a vacuum pipe

- 2 x level sensors top & bottom

- Temperature transmitter

- Pressure sensor

- Fittings: TRI-Clams, SMS, or DIN-ISO

- Built according to EHEDG

Options

- Valve battery for cooling and heating

- Direct steam valves with 5μ ultra filter +valves

- Powder funnels (100l, 250l, 500l, 1000l & 2000l)

- Powder funnel (25l) for small ingredients incl. manual butterfly valve

- Flash Cooling

- Extra powder valve 2½” butterfly / extra liquid top inlet/sample valve

- MCC panel with inverters

- I/O Panel for connection to master PLC

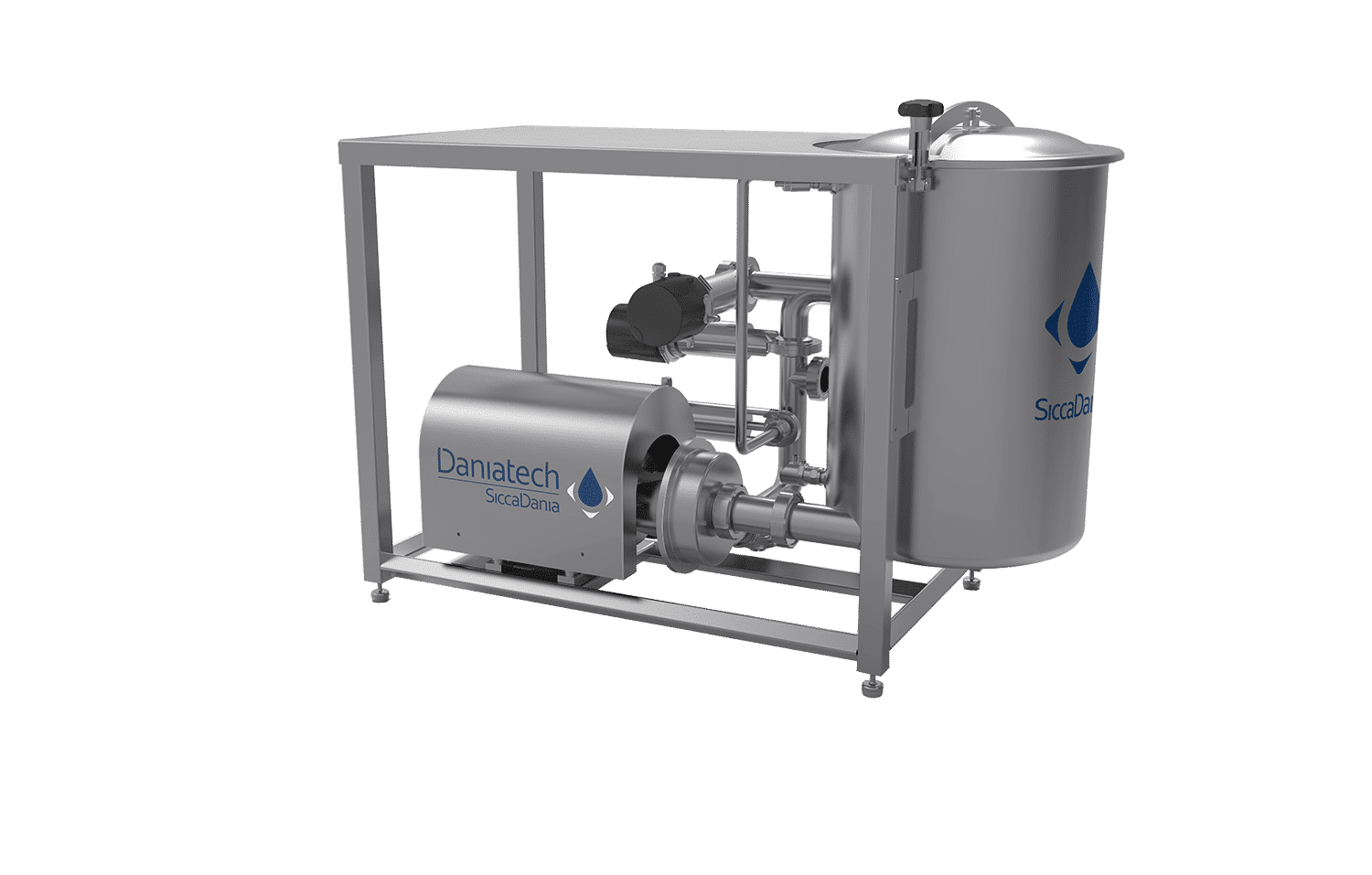

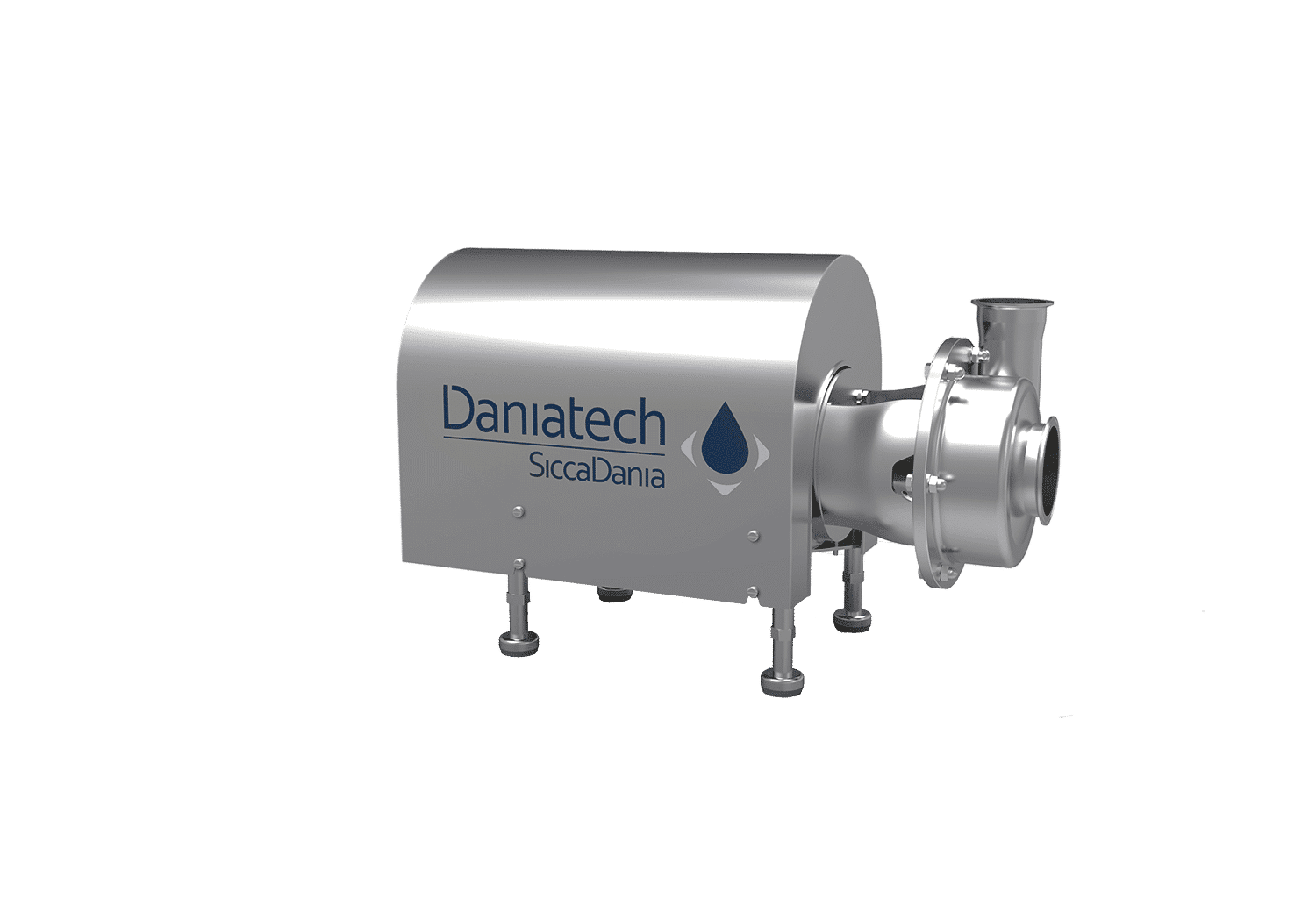

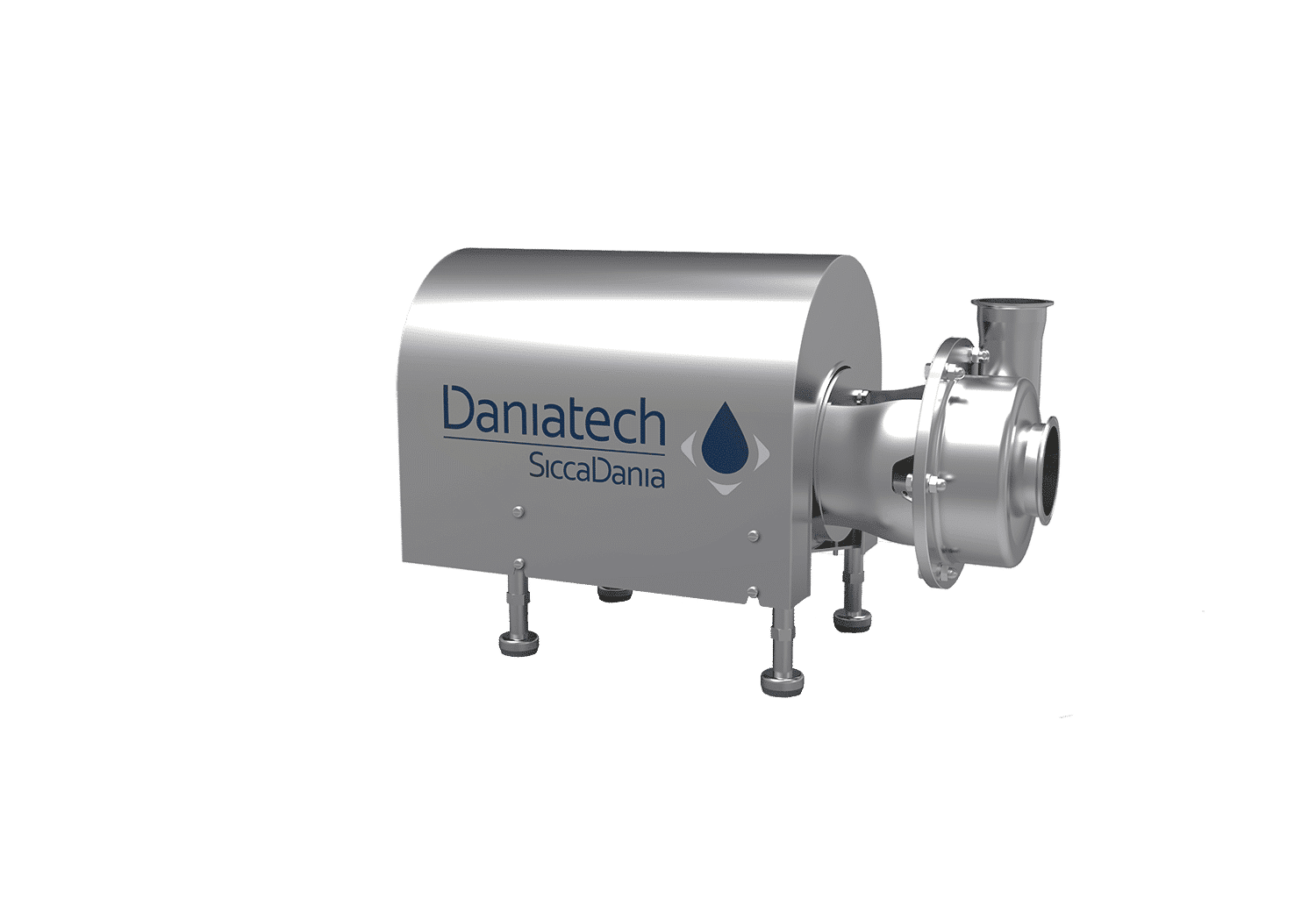

- Outlet pump

- Load cells (2 pc global weighing) with a transmitter in a stainless box

- Process valves – different types are available

- ATEX

- Other motors, NEMA, etc. on request

- Alternative voltage – on request

- PED/ASME/CRN

- Construction according to 3A Design

Applications

The mixer is used for mixing of:

- Sauce

- Mayonnaise

- Dressing

- Gels

- Cream

- Emulsion

- Etc.

Homogenisation down to 3µ lump-free and viscosity up to 50.000 cP.

| Model | Mixer size | Steam Jacket | Direct steam | Cooling Water | Mixer effect | Vacuum pump | Agitator |

| 250 | 160 | 300 kg/h | 300 kg/h (1) | 10 m3/h | 18,5 kW | 3 kW | 1.5 kW |

| 500 | 160 | 400 kg/h | 300 kg/h (1) | 10 m3/h | 22,5 kW | 3 kW | 1.5 kW |

| 1000 | 200 | 500 kg/h | 600 kg/h (2) | 15 m3/h | 30 kW | 5.5 kW | 3 kW |

| 2000 | 250 | 600 kg/h | 600 kg/h (2) | 15 m3/h | 55 kW | 5.5 kW | 3 kW |

| 3000 | 325 | 800 kg/h | 900 kg/h (3) | 20 m3/h | 75 kW | 7.5 kW | 5.5 kW |

| 5000 | 325 | 1000 kg/h | 1200 kg/h (4) | 20 m3/h | 90 kW | 7.5 kW | 7.5 kW |

| Model | Outlet/U | Powder valve | CIP | Inlet | Service Water | Dimensions (H x W x D) | Shipping weight | Shipping volume |

| 250 | Ø51/650mm | 1 x Ø51 1 x Ø63,5 |

Ø51 | 1x Ø51 | 100 l/h | 2400 x 1300 x 1000 mm | 600 kg | 3.1 m3 |

| 500 | Ø51/650mm | 1 x Ø51 1 x Ø63,5 |

Ø51 | 1x Ø51 | 100 l/h | 2600 x 1400 x 1100 mm | 900 kg | 4.0 m3 |

| 1000 | Ø63,5/650mm | 1 x Ø51 1 x Ø63,5 |

Ø51 | 1x Ø51 | 100 l/h | 3600 x 1500 x 1300 mm | 1400 kg | 7.0 m3 |

| 2000 | Ø63,5/650mm | 2 x Ø63.5 | Ø51 | 2x Ø51 | 100 l/h | 4000 x 2100 x 1800 mm | 1800 kg | 15 m3 |

| 3000 | Ø76/1200mm | 2 x Ø63.5 | Ø51 | 2x Ø51 | 150 l/h | 4500 x 2600 x 2100 mm | 2200 kg | 24.5 m3 |

| 5000 | Ø76/1200mm | 2 x Ø63.5 | Ø51 | 2x Ø51 | 150 l/h | 4800 x 2700 x 2300 mm | 2300 kg | 30 m3 |