Specifications

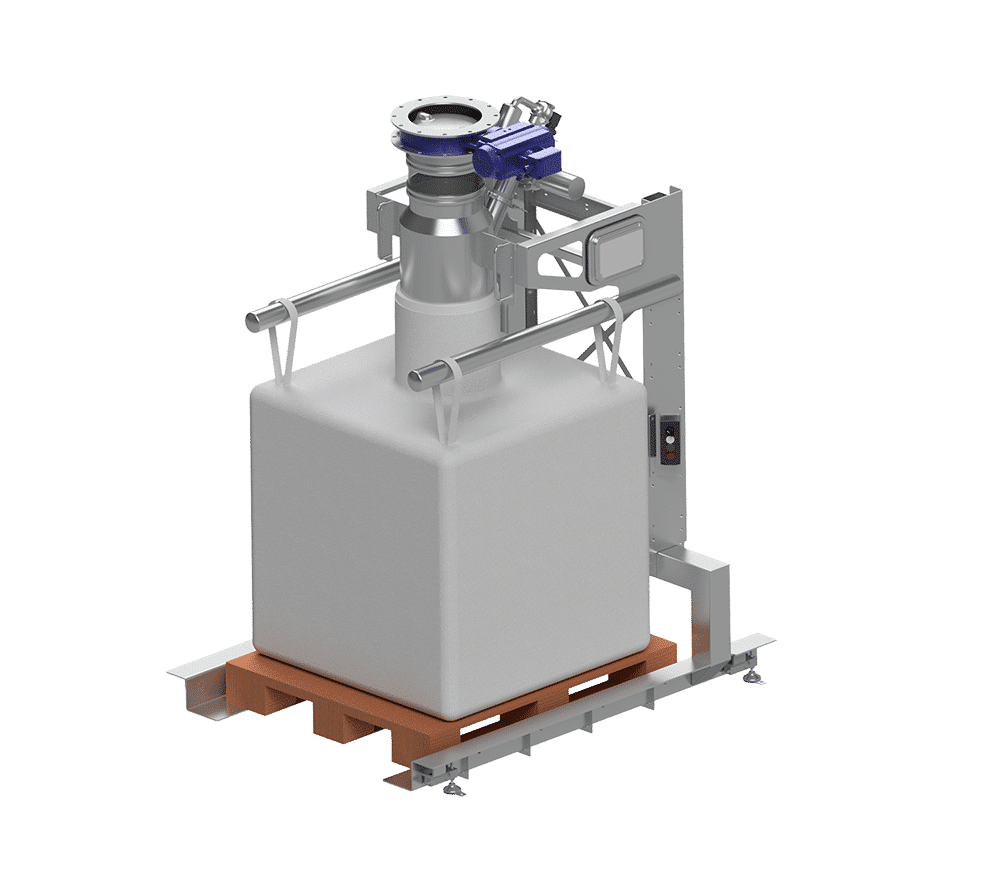

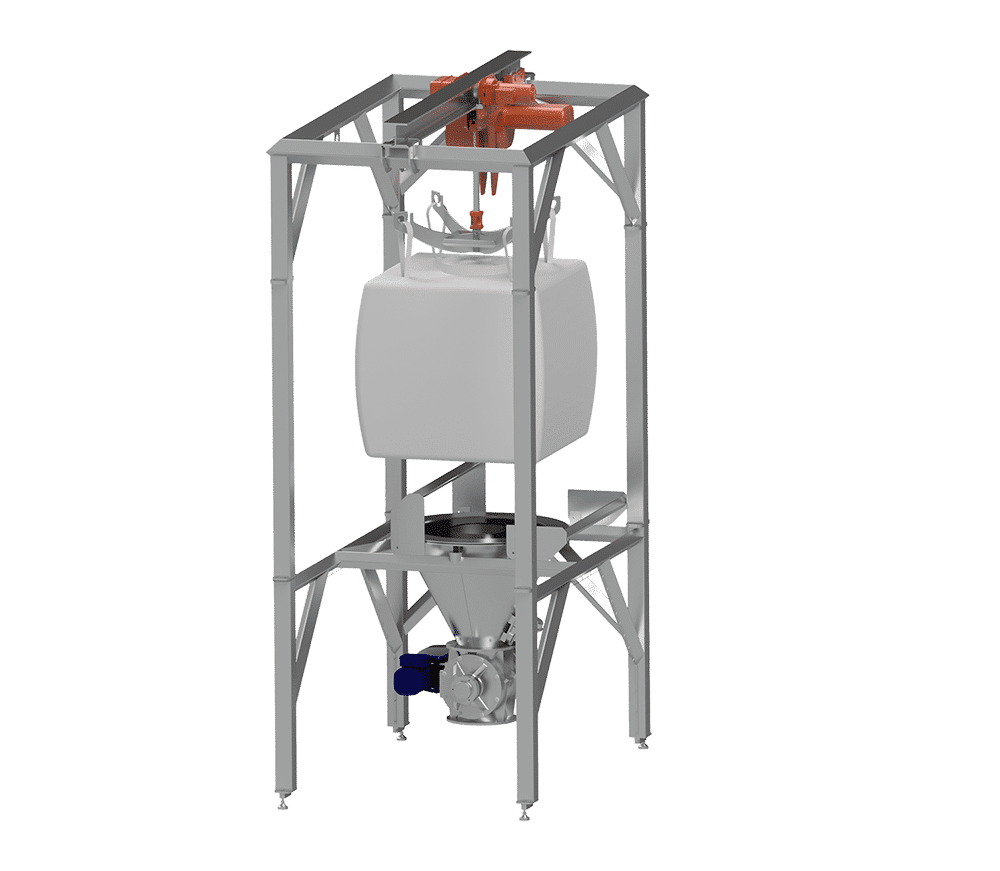

The Bigbag Filling Master (BFM) is an ergonomic, flexible and effective unit that can be adapted to different types of bigbags with a filling capacity of up to 20 bigbags pr. hour, depending on size and product.

The BFM filling station includes an inflatable dust-tight connection to the bigbag inlet spout, and the bigbag lifting straps hang on manually adjustable supports (forks).

This provides good working conditions when handling different types of bigbags. The filling pipe is designed with an inflatable connection for empty bigbags, evacuation of excess air from powder filling through a filter, shut-off butterfly valve and compressed air cleaning before changing bigbag to avoid powder dust.

The filling head includes lifting strap hooks that can manually/automatically be adjusted both in height and width to ensure a correct filling of the actual bigbag. The filling sprout on the bigbag is manually placed on the inflatable bellows, which, when filled with air, creates a dust-tight connection.

As bigbag filling supplier we offer:

- Ergonomic design for better working conditions

- Hygienic design in compliance with EHEDG

- Closed system with low dust emission

- Easy access to operate the system

The Bigbag Filling Master is a flexible system that can complete a wide range of bigbag filling systems, making it possible to meet the various demands in the food, chemical and pharmaceutical industries.

Equipment

The Bigbag Filling Master (BFM) is designed with our customers in mind. The BFM includes:

- Stainless steel support structure with easy access for adjustment and operation

- Stable support to ensure easy replacement of bigbags

- Forks with rounded edges to secure the straps and ensure easy sliding of the straps during replacement

- Manual/automatic adjusted filling head

- Inflatable bellow on the filling sprout

- Filter for evacuated air during filling of the bigbag

Options

- Automatic raising/lowering of filling head and bigbag lifting strap suspension

- Load cells and weighing computer

- Electrical vibrator bottom plate

- Roller conveyor

- Automatic pallet insertion

- Dust extracting around the filling head

- Working platform

- Fan with connection to the filling head to replace compressed air for filling of the bigbags

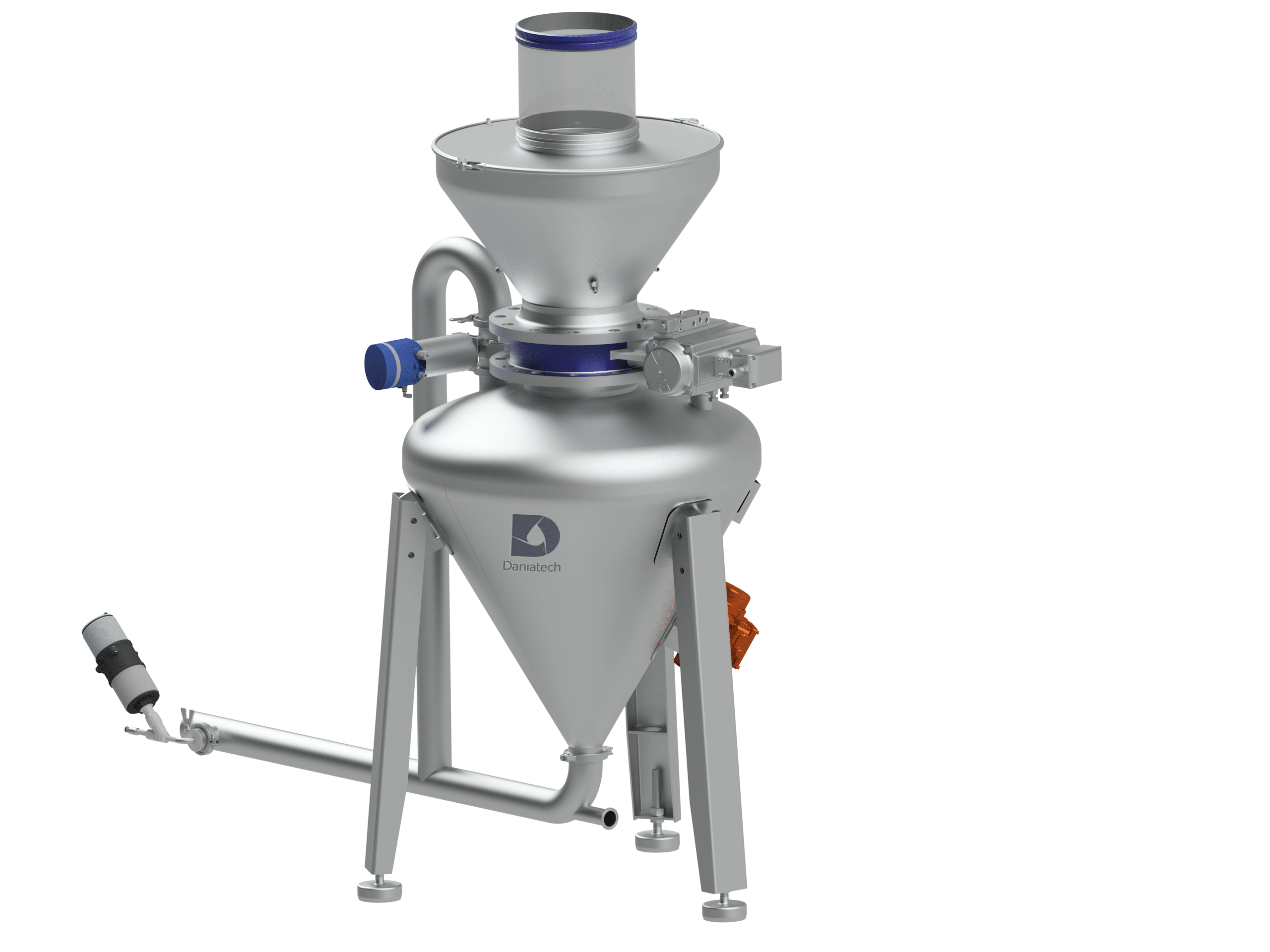

- Hopper with functions as a receiver cyclone, weighing hopper or with N2 addition to the powder

- Stretch wrapping of bigbags

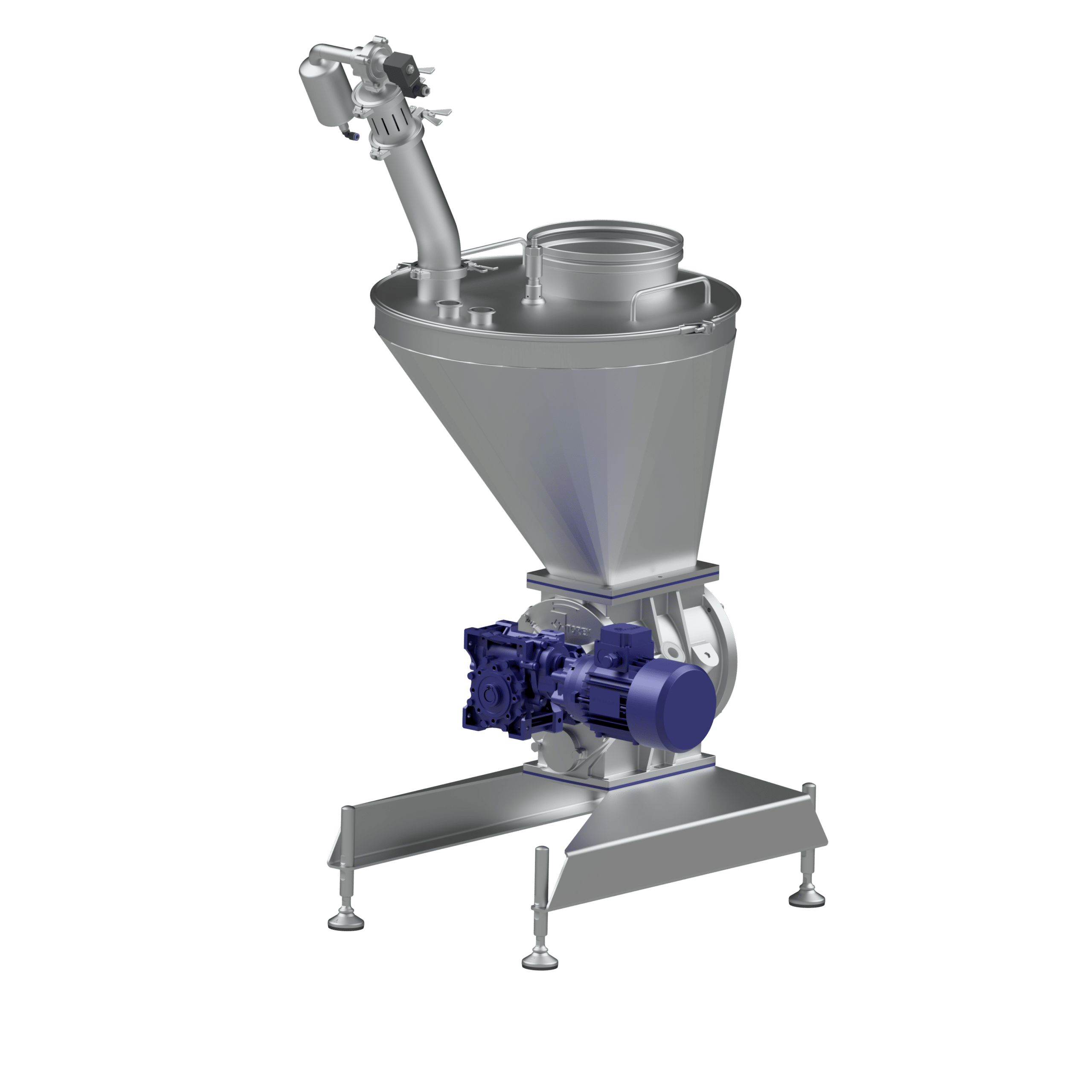

- Dosing device (rotary valve, screw feeder or a vibrator feeder)

- Puls welding of the bigbag inlet sprout

- Sieve, magnet or a lump breaker

- Filling for drums

- Grounding Clamp

- Central PLC control system

- Other ATEX zones

As bigbag filling supplier we offer:

- Ergonomic design for better working conditions

- Hygienic design in compliance with EHEDG

- Closed system with low dust emission

- Easy access to operate the system

The Bigbag Filling Master is a flexible system that can complete a wide range of bigbag filling systems, making it possible to meet the various demands in the food, chemical and pharmaceutical industries.

Connections

| Supply of dry compressed air according to the specifications (typical, up to 7 bar, 2 – 20 m3/h hour, depending on the capacity). |

| Power supply: 3×400 VAC, 50 Hz + PE |

Bigbag size according to EN21898

| Volume: | 0.5 – 2 m3 |

| Height (max) | 2200 mm |

| Lifting straps: | 300 mm |

| Filling spout: | Ø350 – 450 mm |