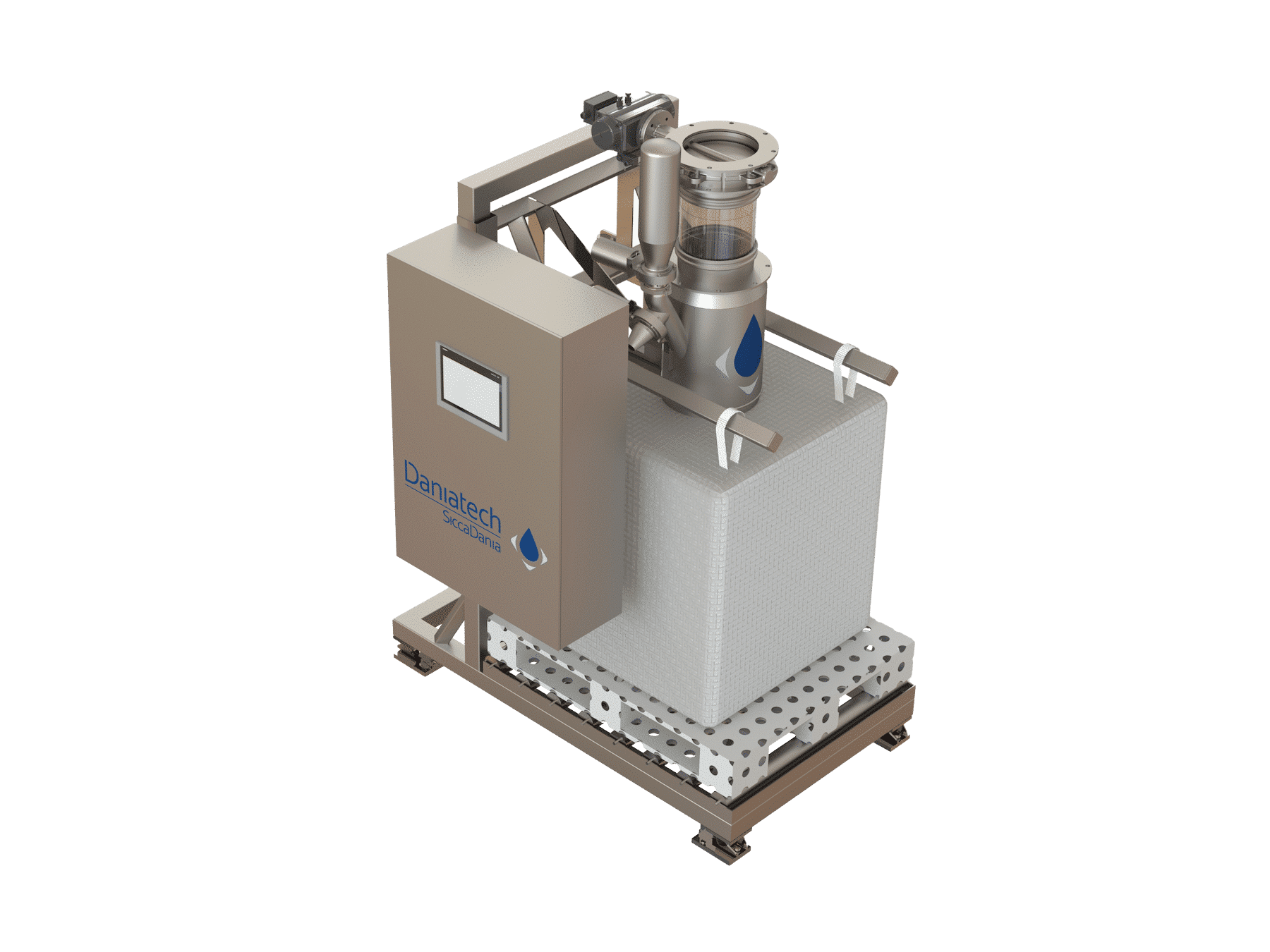

Vacuum conveying systems

Vacuum dilute phase systems operate in a vacuum under atmospheric pressure. This system is generally used for conveying bulk material from multiple intakes through a pipeline to an individual destination. Here, powder is separated from air through a vacuum filter.

Through an intake, the powder is dosed into the airflow and transported in a continuous flow at a relatively high velocity, through the pipeline to the dedicated destination. The vacuum pump includes a pressure transmitter to protect the powder-to-air-ratio in order to avoid blockage.

Unlike the pressure conveying system, the vacuum system easily picks up bulk material from an intake and does not heat up the product. The vacuum system has superior leak containment and is often used where there is a demand for cleanliness and ATEX considerations.

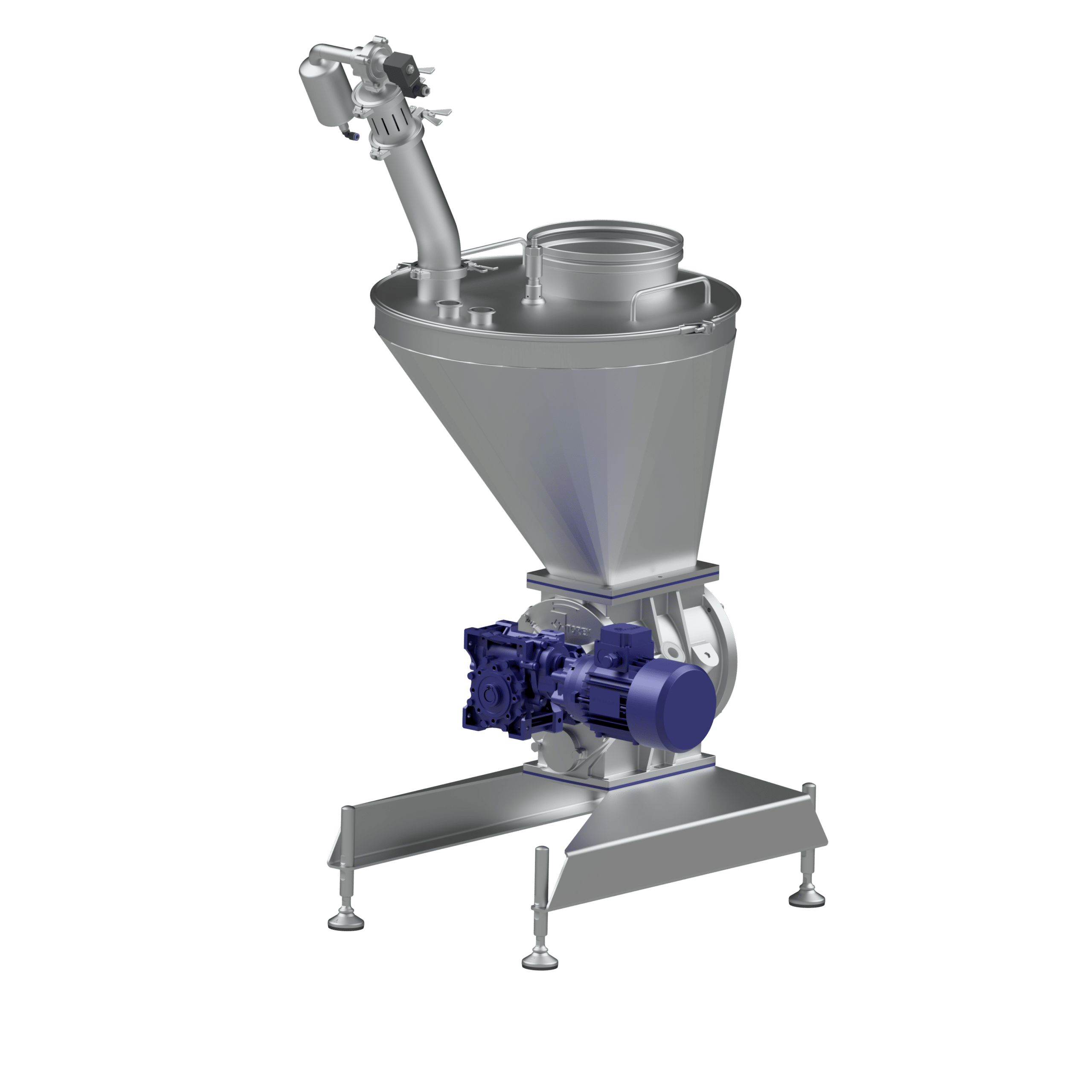

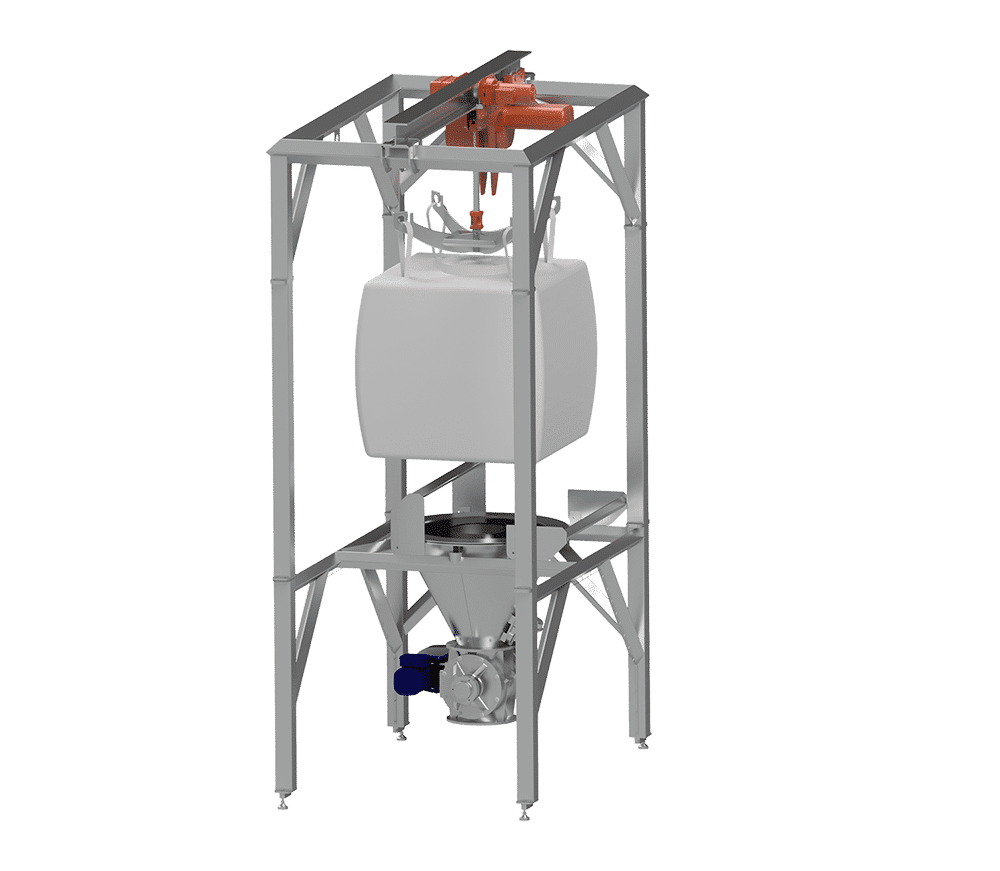

Daniatech vacuum airlock hopper with breathing filter, level sensor and service manway.

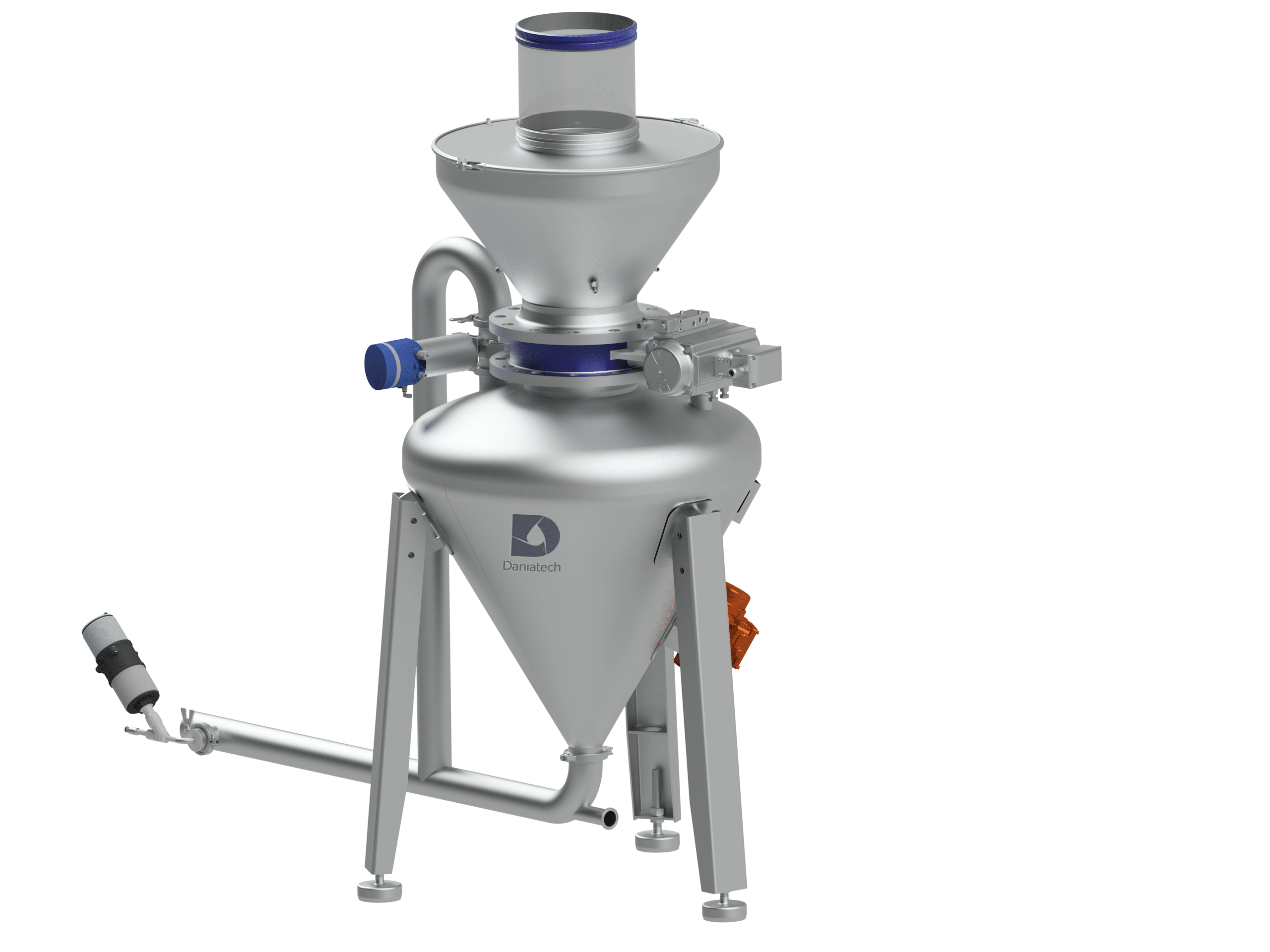

Pressure conveying systems

Positive pressure dilute phase systems operate above atmospheric pressure. This system is used to convey bulk materials from single or multiple intakes through a pipeline to one or more destinations. Here, powder is separated from air through a filter.

Through an airlock, powder is dosed into the airflow and transported in a continuous flow at a relatively high velocity, through the pipeline to the dedicated destination. The blower pump is equipped with a pressure transmitter to protect the powder-to-air-ratio in order to avoid blockage in the pipeline.

Pressure systems typically have higher capacities and can convey product over further distances than a vacuum system.

Daniatech pressure airlock hopper is equipped with air leakage venting, level sensor and service manway. The Daniatech airlock ensures a gentle product flow.

Pressure conveying systems

Equipment

The pressure conveying system is designed with our customers in mind according to the actual circumstance and can include:

- Air intake (filter)

- Blower air pump

- Pressure transmitter

- Rotary valve, Airlock system with filter

- Stainless steel pipe transport line

Options

- Air intake (HEPA-filter), cooling and dehumidification

- Air pump with silence damper

- Weighing and dosing equipment

- Delumping

- Transport line including Stainless steel pipe, elbows, 2-way valves and flexible connection

- Reinforced bends

- Inline sifter, magnetic detection and separation

- ATEX

- Filter receivers, cyclone separators and silos

Vacuum conveying systems

Equipment

The vacuum conveying system is designed with our customers in mind and can include:

- Air intake (filter)

- Dosing system, screw feeder, rotary valve, airlock system with filter

- Stainless steel pipe transport line

- Vacuum air pump

- Pressure transmitter

Options

- Air intake (HEPA-filter), cooling and dehumidification

- Vacuum air pump with silence damper

- Weighing and dosing equipment

- Delumping

- Transport line including stainless steel pipe, elbows, 2-way valves and flexible connection

- Reinforced bends

- Inline sifter, magnetic detection and separation

- ATEX

- Vacuum filter receivers, cyclone separators and silos

Pressure conveying systems

| Capacities | 0.1 – 10 ton/h |

| Transport velocity | 20 – 30 m/s |

| Transport distance | up to 100 m |

| Operating pressure | above 1 bar |

Vacuum conveying systems

| Capacities | 0.1 – 10 ton/h |

| Transport velocity | 20 – 30 m/s |

| Transport distance | up to 100 m |

| Operating pressure | 500 mbar vacuum |