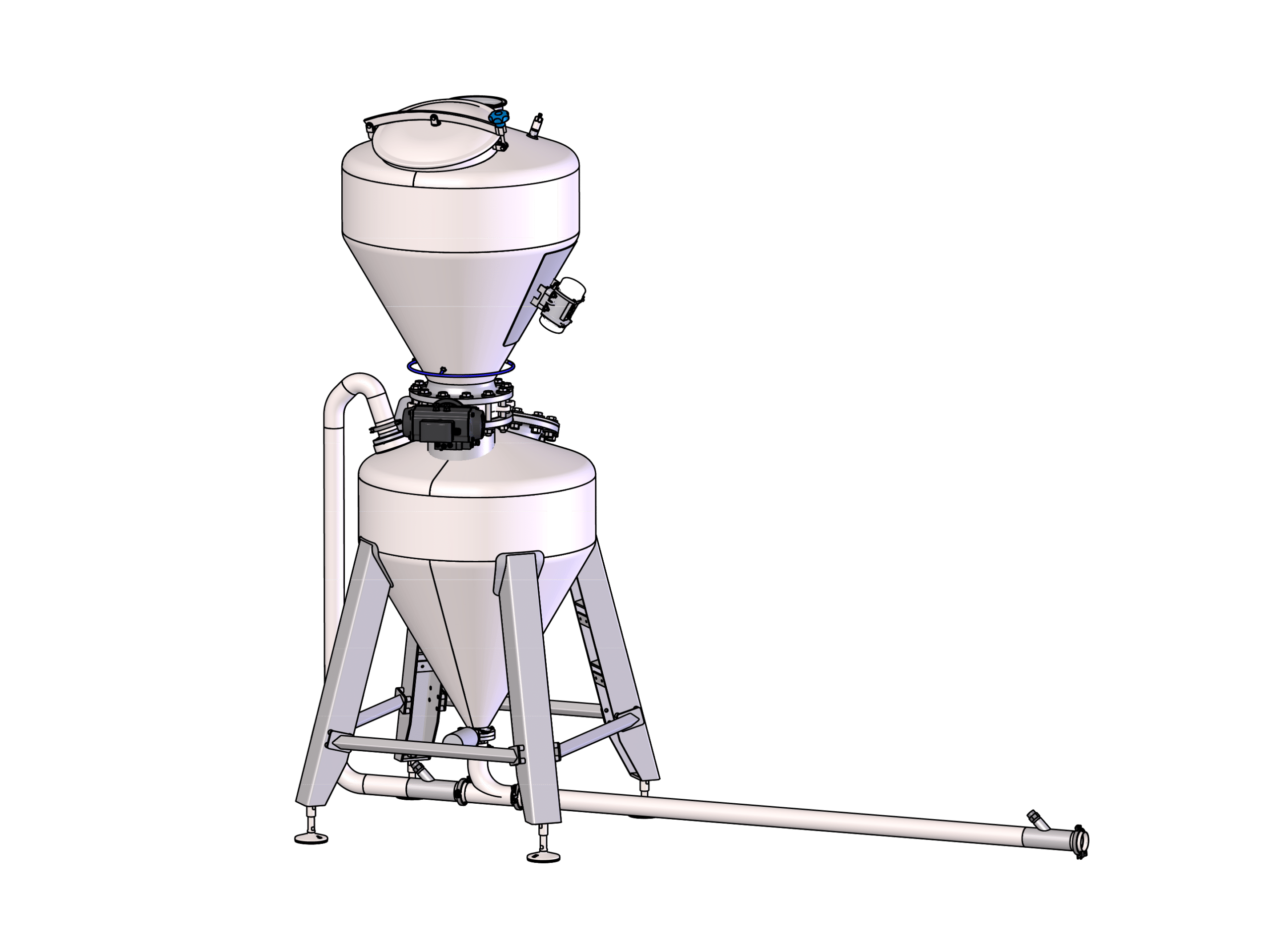

Specifications

The Dense-Phase Master represents the next generation of gentle conveying of powder/granulate solutions for the process industry.

- High conveys capacities over long distances to several receivers

- Low conveying velocity (1-10 m/s)

- Operational pressure (<7 bar typical 1-3 bar)

- Efficient and gentle handling of abrasive and fragile material

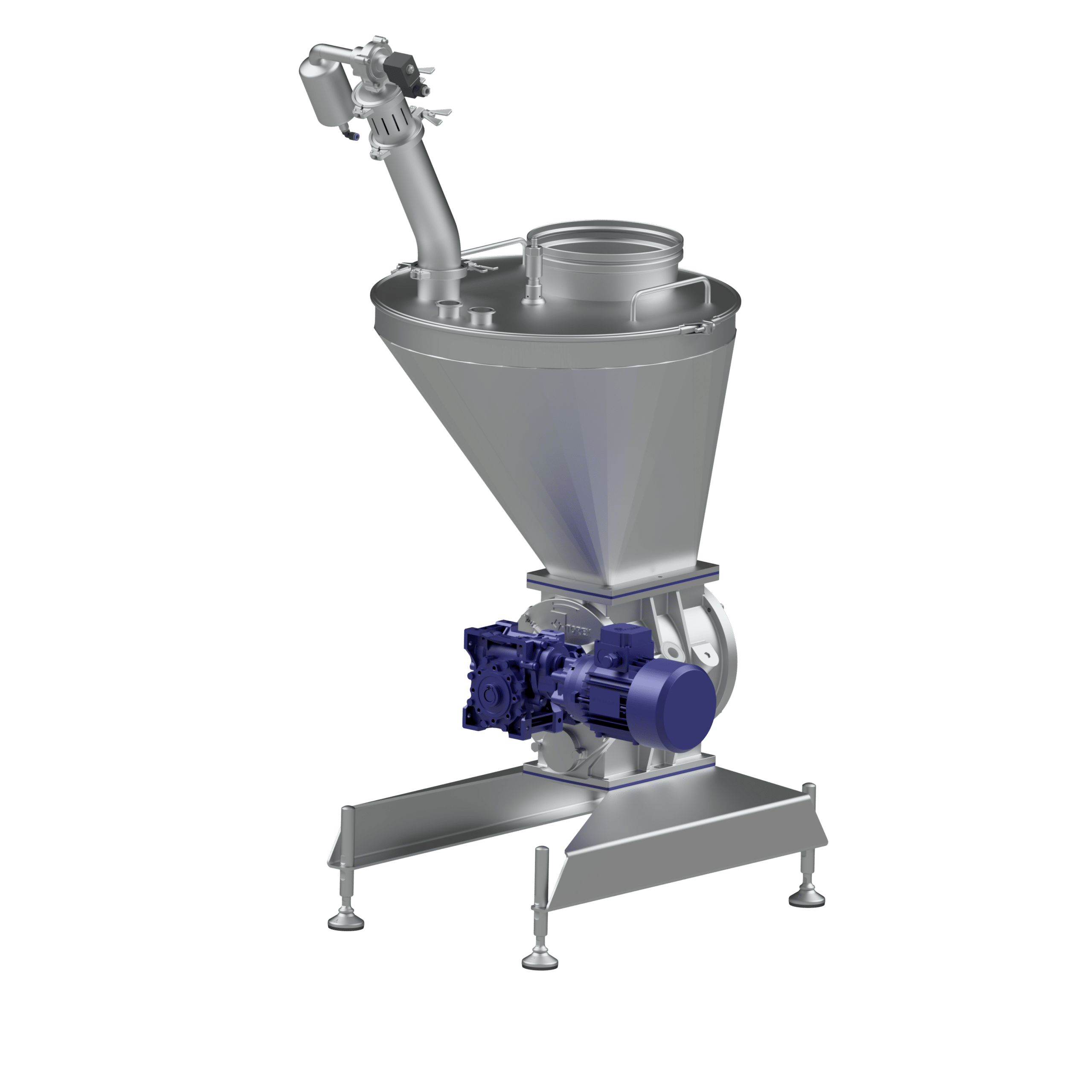

Dense-phase pressure conveying systems use compressed air to push the product from a sending pressure vessel through a pipeline to one or several destinations.

The powder movement is controlled by adjustable air valves in connection with pressure transmitters to keep a constant pressure.

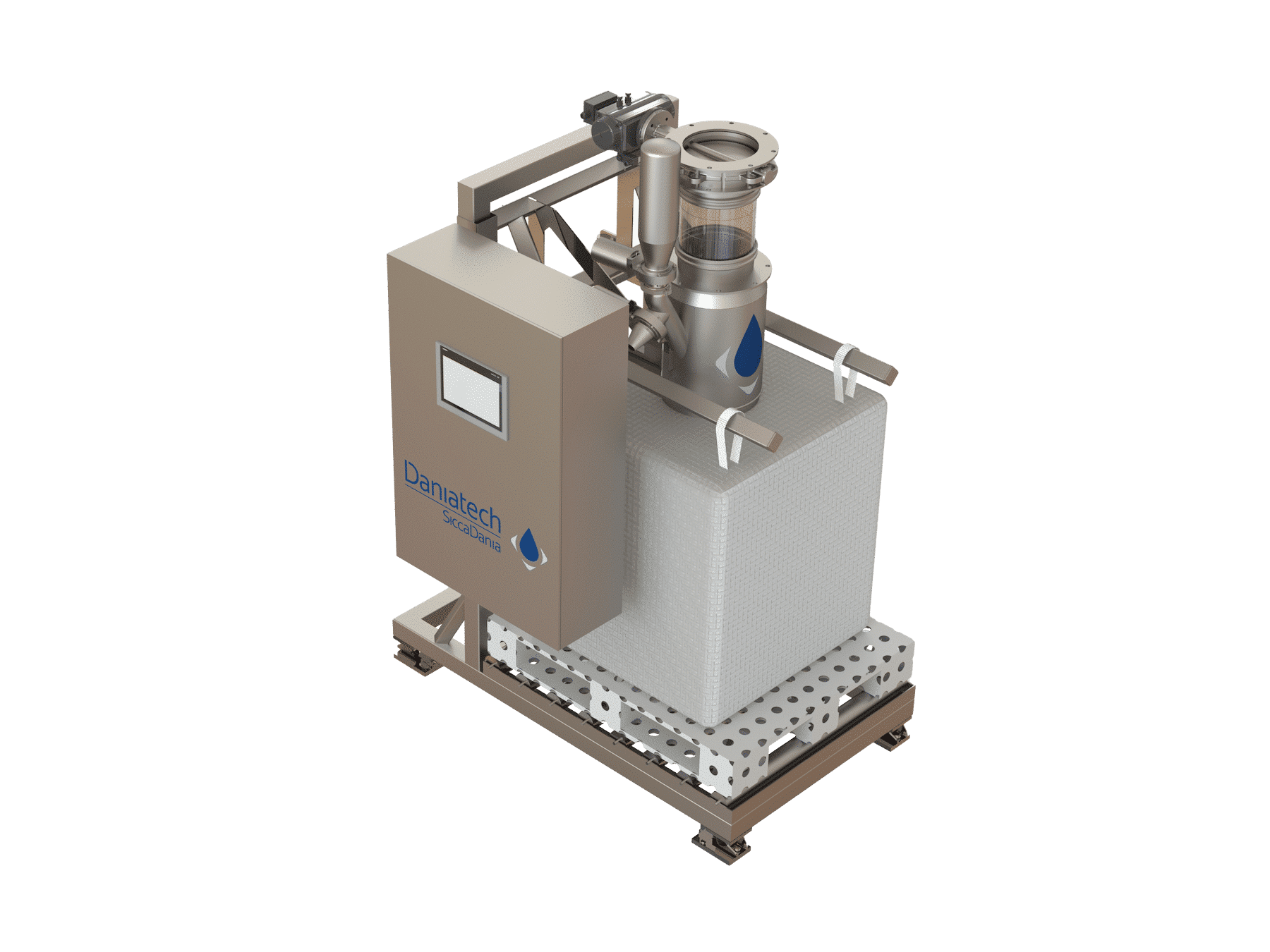

The system is a robust design in stainless steel with few moving parts. The system is delivered with a pneumatic control panel with regulation valves and pressure sensors for achieving the highest level of economical and gentle powder transport.

The system is manufactured according to the EN 1935/2004 and the pressure tank according to (PED) 2014/68/EU.

Advantages

The Dense-Phase Master provides our customers with a smaller filter area, minimal maintenance and better economy – all achieved through innovative design.

As dense-phase supplier we offer:

- Low energy consumption/high efficiency

- Fast and easy installation

- Low service cost – few wear parts

- Hygienic design in compliance with EHEDG

- Customisable design according to capacity and product

The Dense-Phase Master is an energy-efficient and flexible powder conveying system.

Standard Equipment

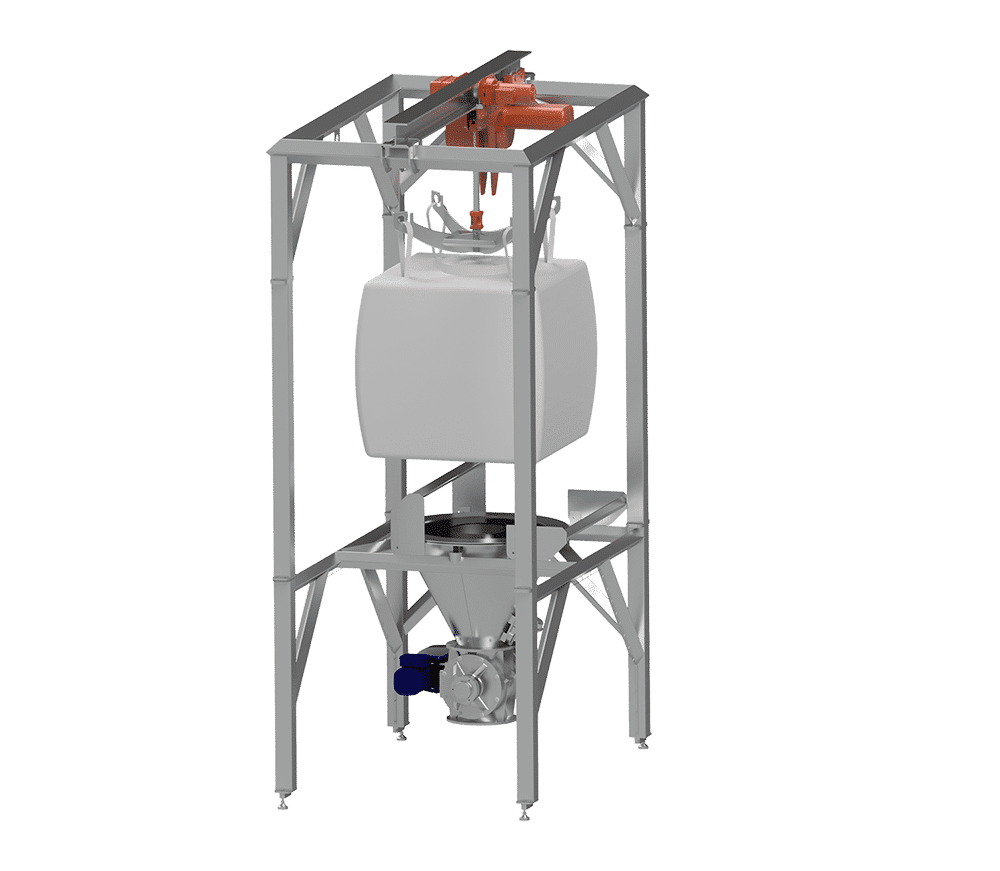

- Pre-hopper with level indicator, fluidising and filter

- Sending pressure vessel with level sensor, valves and injector

- Pneumatic control cabinet

- Regulation valves

- Flowmeters

- Pressure sensors

- Safety valves and contra valves to control the airflow for the product conveying

- Moveable control cabinet

Options

- Twin system, with two sending vessels to provide continuously conveying and lower installation height

- PLC system for control of the system

- Air injectors to fluidize the product to reduce friction

- Line boosters to assist during the pipeline

- Pulsed air supply to break up the product into plugs in the pipeline

- Inline product sampler

- Magnet and metal detection

- Weighing system for recording the sending capacity to the dedicated receiver

- Pipeline and 2-way valves

As dense-phase supplier we offer:

- Low energy consumption/high efficiency

- Fast and easy installation

- Low service cost – few wear parts

- Hygienic design in compliance with EHEDG

- Customisable design according to capacity and product

The Dense-Phase Master is an energy-efficient and flexible powder conveying system.

Connections

| Supply of dry compressed air according to the specifications in the actual quoted system (typical, up to 7 bar and from 50 to 200 m3/h hour, depending on the capacity and the distance). |

| Power supply: 3×400 VAC, 50 Hz + PE |