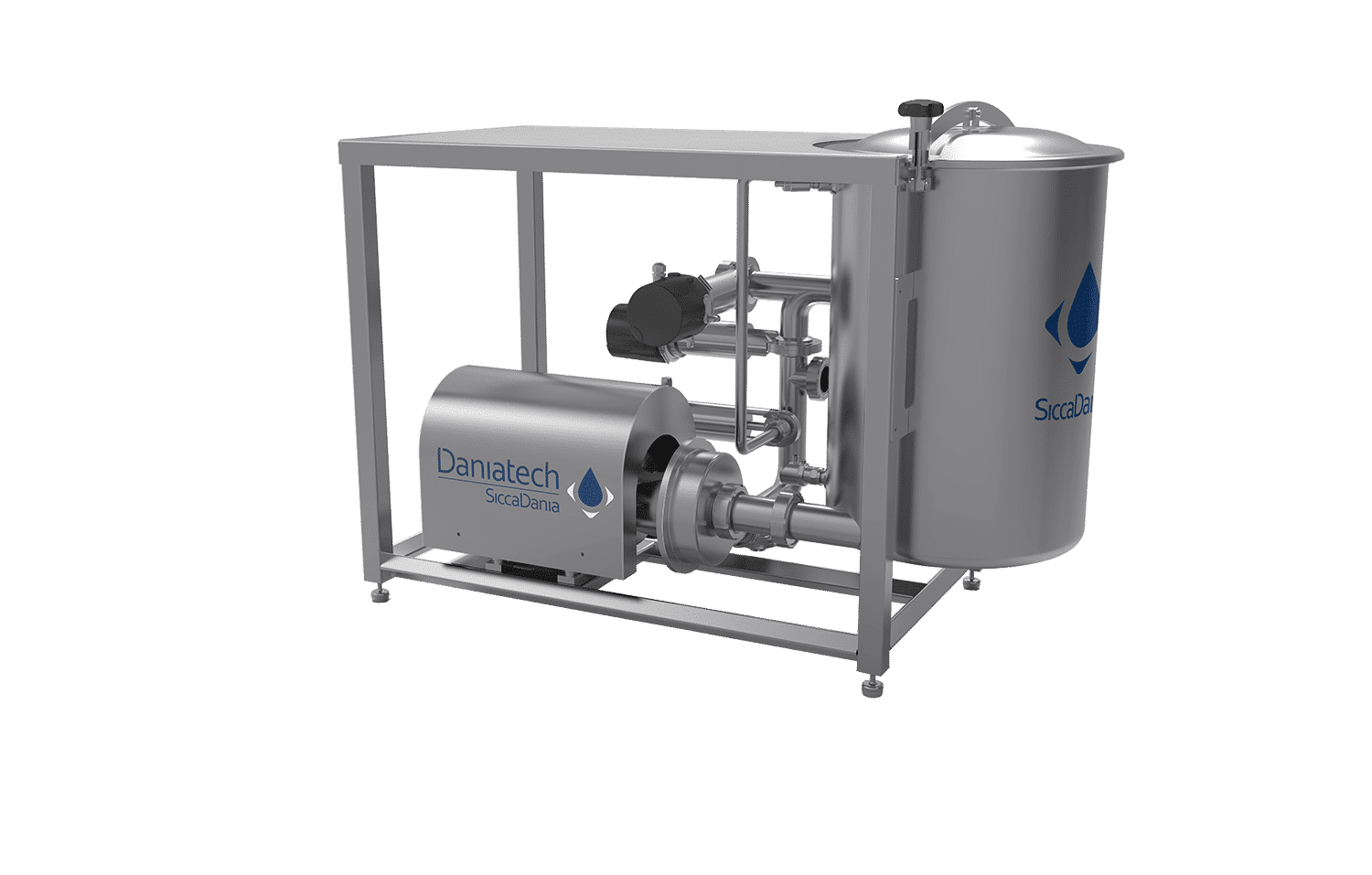

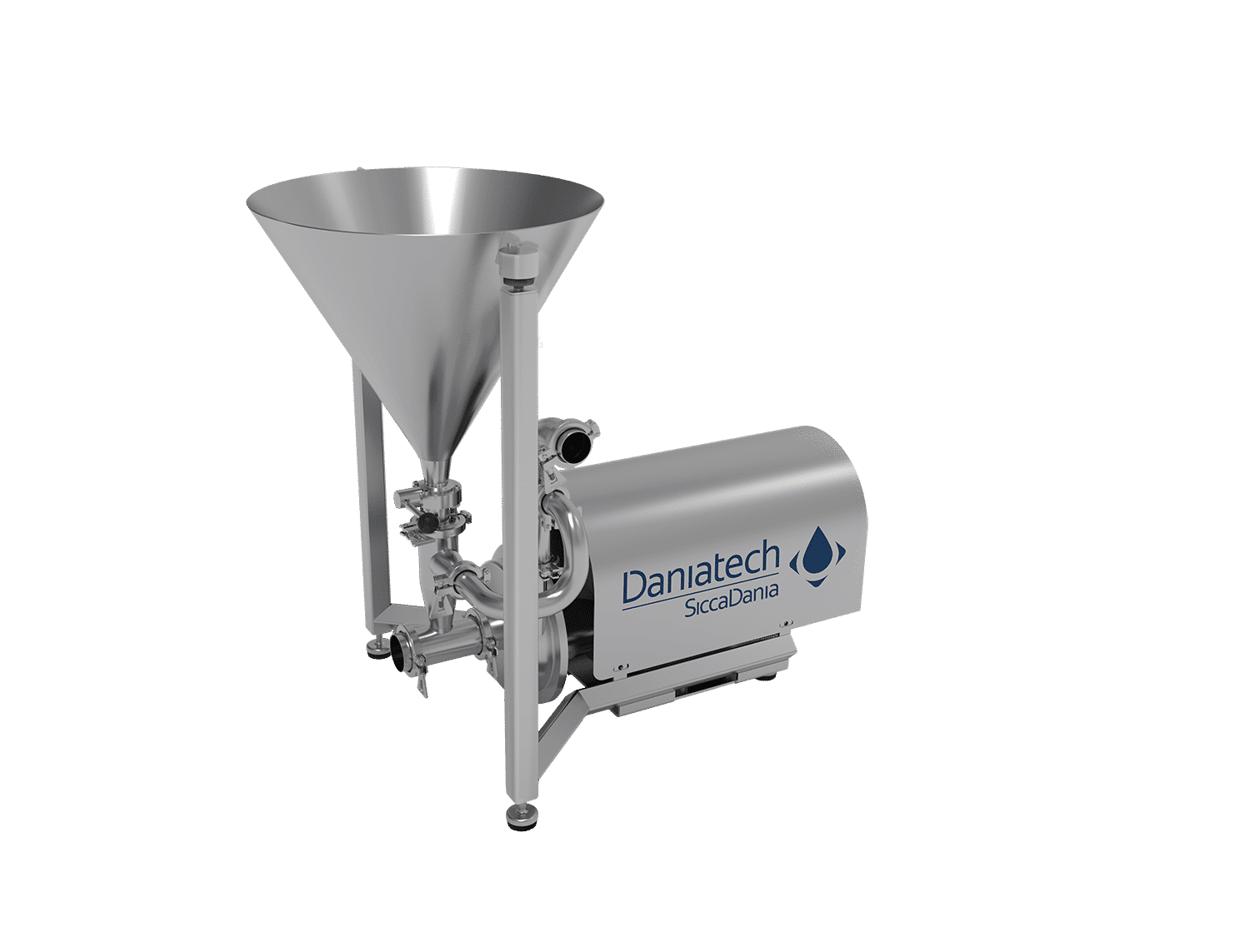

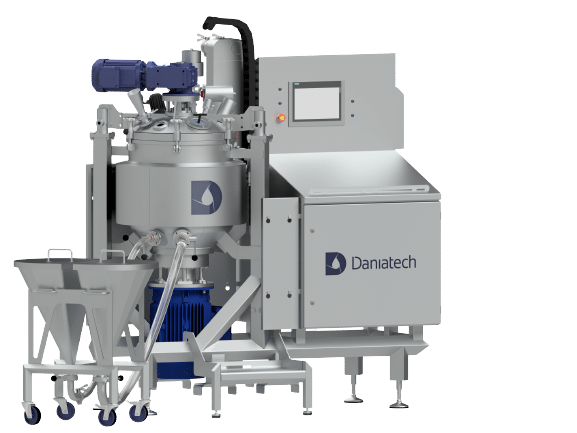

The LiquidMaster works according to the rotor-stator principle, where a special closed mixing wheel distributes the product through the patented slots. The unit circulates approx. 75% of the liquid back into the vessel.

The powder is dosed manually into the vessel where the liquid level is manually controlled by a butterfly valve on the inlet pipe.

The mixer can be used in many setups and applications. For low to medium viscosity products, the mixer performs the out-pumping action itself. For high-viscose applications (>250 cP), the setup requires positive feeding.

The mixer is integrated into a table that offers an ergonomic working position.

Applications:

The LiquidMaster is used for mixing of:

- Powders and liquids

- Sugar solutions

- Recombined dairy products

- Emulsifiers and stabilisers

- Brine

- Etc.

Homogenisation down to 1µ lump-free.

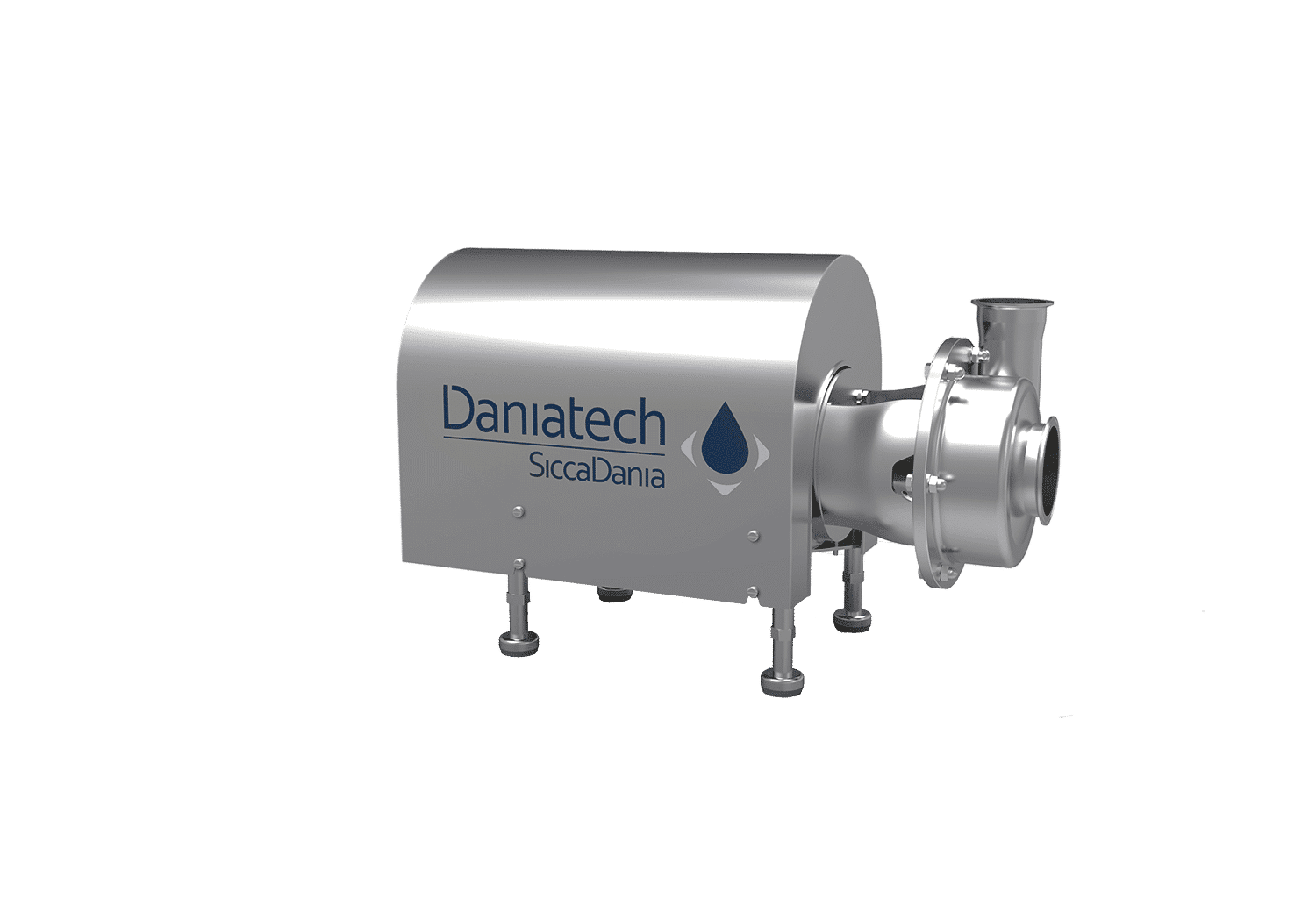

Standard Equipment

- Mixer unit (230/400 V 50 Hz) with shaft sealing

- Tri-clamp inlet/outlet

- CIP spray ball with manual butterfly for cleaning

Options

- Double mechanical shaft seal with Bürkert (1/8”) solenoid valve and throttle valve

- Control cabinet with Start/Stop

- Control cabinet with speed control

- Fitting: SMS DIN/ISO. Other on request

- ATEX

- Other motors, NEMA, etc. on request

- Alternative voltage – on request

Applications:

The LiquidMaster is used for mixing of:

- Powders and liquids

- Sugar solutions

- Recombined dairy products

- Emulsifiers and stabilisers

- Brine

- Etc.

Homogenisation down to 1µ lump-free.

| Model | Motor | Flow | Mixer capacity | Tank volume | Powder capacity |

| LiquidMaster 50-160 | 7.5 kW | 25 ms/h | 15 ms/h | 200 l | 40 – 60 kg/min |

| LiquidMaster 50-160 | 11 kW | 30 ms/h | 20 ms/h | 200 l | 60 kg/min |

| Model | Inlet pressure | Outlet pressure | Service water* | Weight | Dimensions (H x W x D) |

| LiquidMaster 50-160 | 0.5 bar | 2 bar | 20 l/h | 150 kg | 970 x 750 x 1600 mm |

| LiquidMaster 50-160 | 0.5 bar | 2 bar | 20 l/h | 200 kg | 970 x 750 x 1600 mm |

*When flushed, the mechanical seal is selected