Specifications

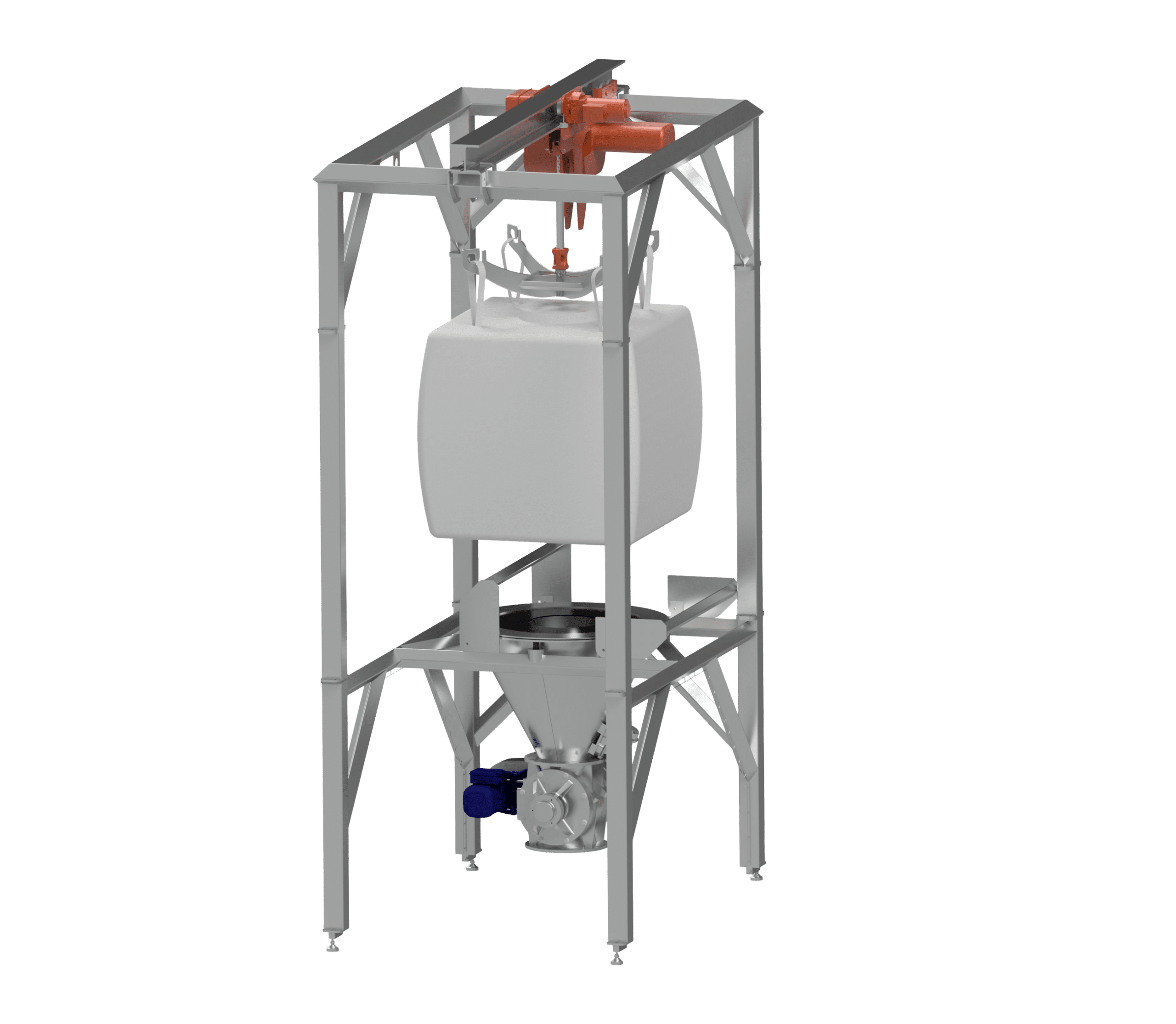

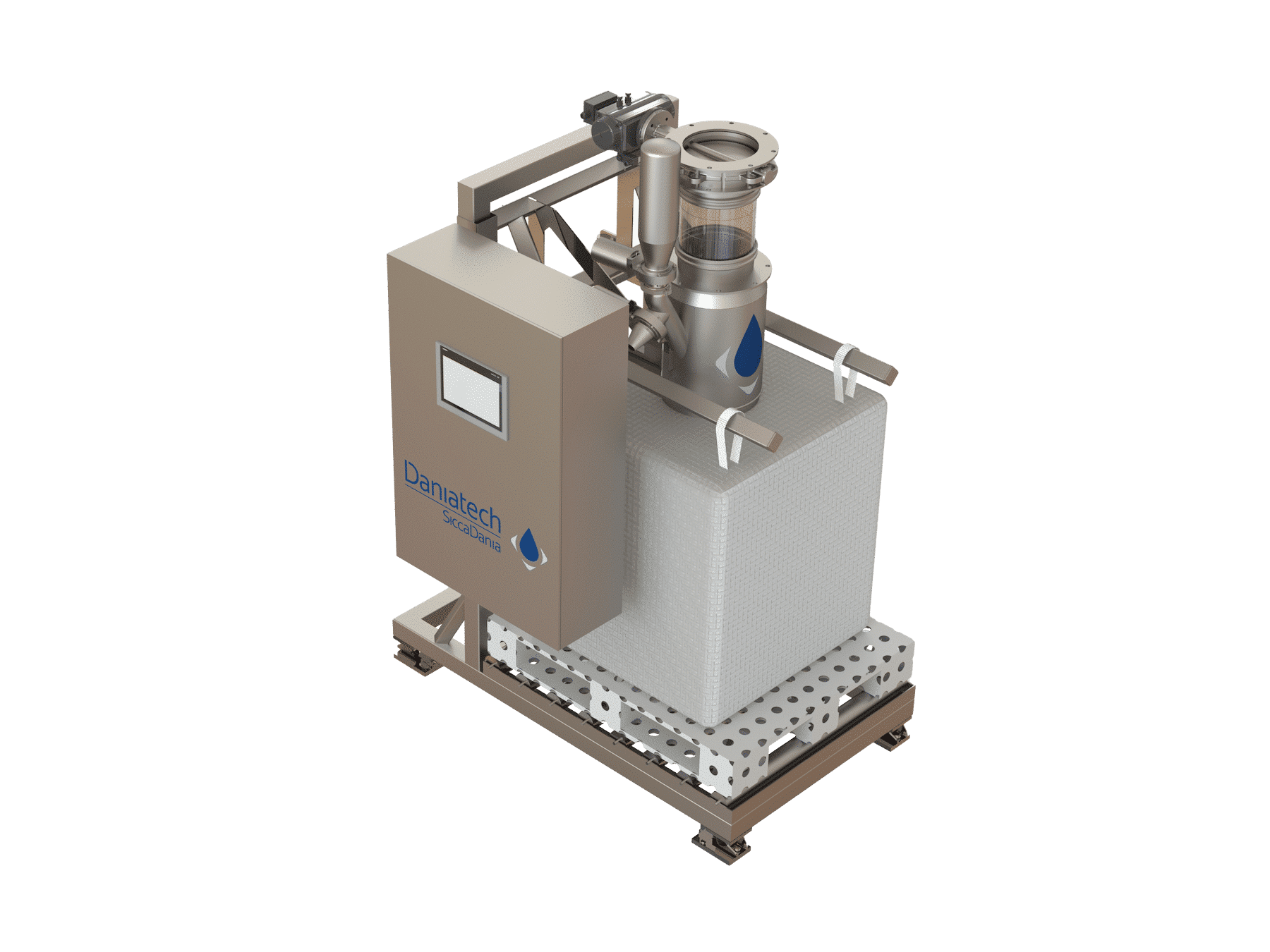

The Bigbag Discharge Master is an ergonomic, flexible and effective unit that can be adapted to different types of bigbags and discharge options, depending on the product and the discharge purpose. The system is a module system with different options for handling bigbags in/out of the rack (forklift handling on a lifting yoke or by an electrical chain hoist).

The system is designed in three modules:

- Bottom section with discharge options

- Middle section in different height, according to bigbag types

- Top section with an electrical hoist or fixed frame for bigbag handling with a forklift truck in a lifting yoke

As bigbag discharge supplier we offer:

- Easy and safe access to operate the system

- Closed system with low dust emission

- Ergonomic design in compliance with EHEDG

- ATEX-compliant solutions

The Bigbag Discharge Master is a flexible system in line with a wide range of other bigbag discharge systems – all designed to meet the various demands in the food, chemical and pharmaceutical industry.

Equipment

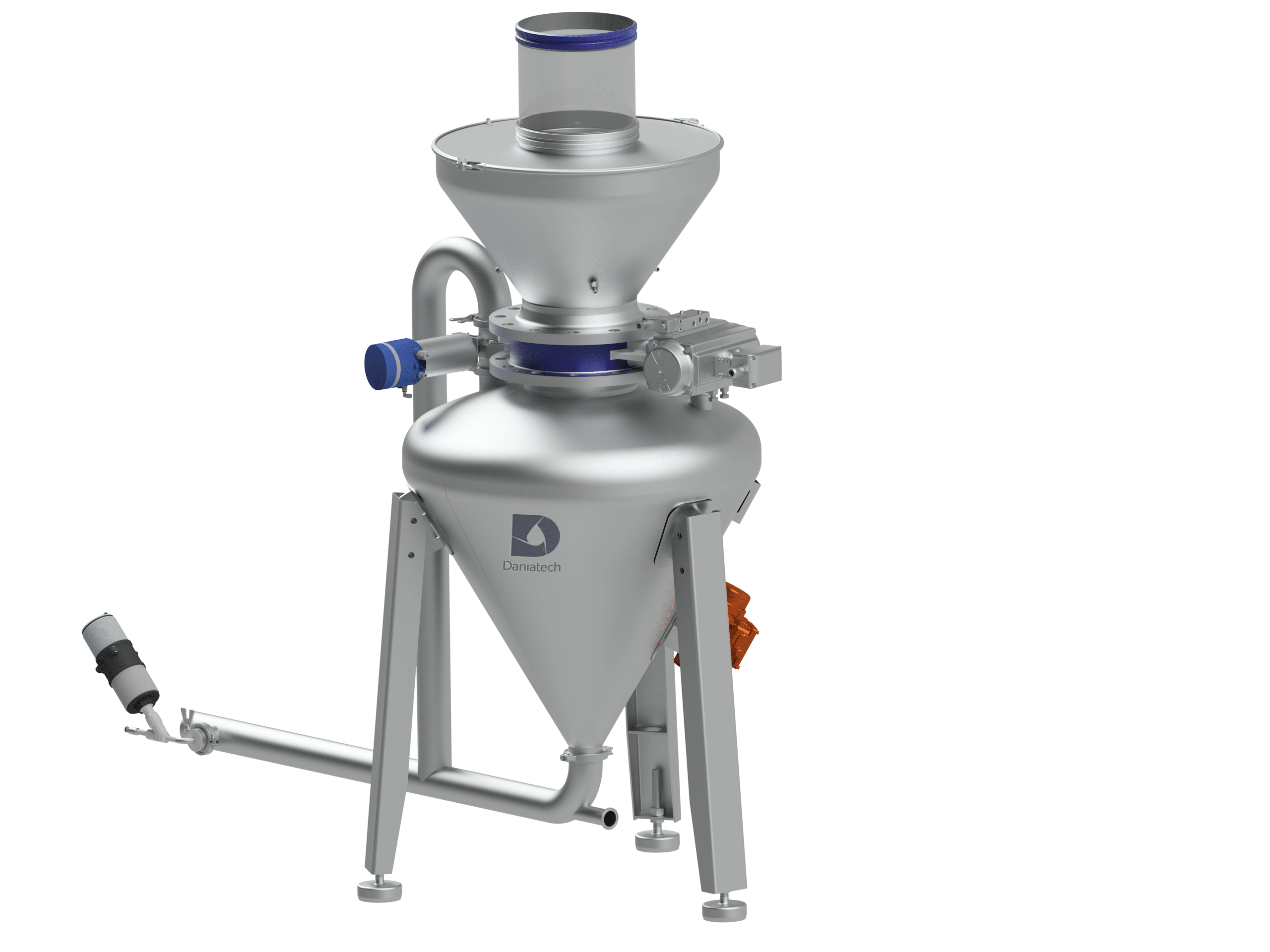

Our Bigbag Discharge Master is very flexible with many options to meet the clients’ demands:

- Buffer-bin

- Flow aids

- Sifters

- Flow magnet

- Combined bag tipping unit

- Clamp functions

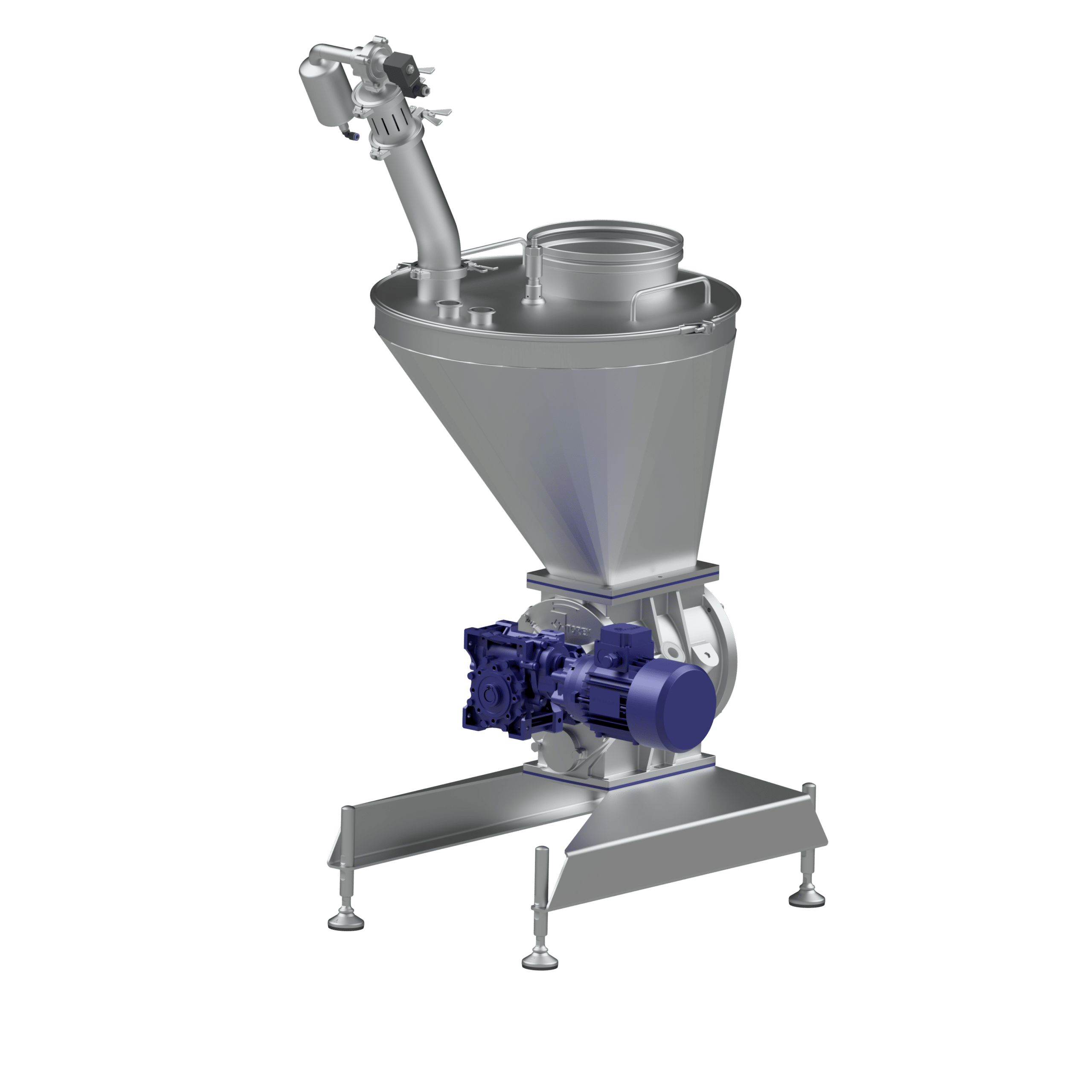

- Connection to dosing systems (rotary valves, screw feeder)

- Connections to pneumatic powder conveying systems

The lifting yoke is designed with a low building height with a safe attachment to the lifting straps on the bigbag.

Options

- Load cells and weighing computer

- Vibrator on the bigbag, fluidiser and vibrator on the outlet funnel

- Dust extracting around the outlet sprout (discharge funnel)

- Iris valve for closing and removing bigbags with content

- Outlet-hopper (different sizes available)

- Dosing device (rotary valve, screw feeder or a vibrator feeder)

- Fan with connection to the filling head to replace compressed air for filling of the bigbags

- Sifter/magnet/lump-breaking

- Working platform

- Grounding clamp

- Central PLC control system

- Other ATEX zones

As bigbag discharge supplier we offer:

- Easy and safe access to operate the system

- Closed system with low dust emission

- Ergonomic design in compliance with EHEDG

- ATEX-compliant solutions

The Bigbag Discharge Master is a flexible system in line with a wide range of other bigbag discharge systems – all designed to meet the various demands in the food, chemical and pharmaceutical industry.

Connections

| Supply of dry compressed air according to the specifications (typically up to 7 bar, 2-10 m3/h |

Bigbag size according to EN21898

| Volume | 0.5 – 2 m3 |

| Height (max) | 2200 mm |

| Lifting straps | 300 mm |

| Filling sprout | Ø350 – 450 mm |