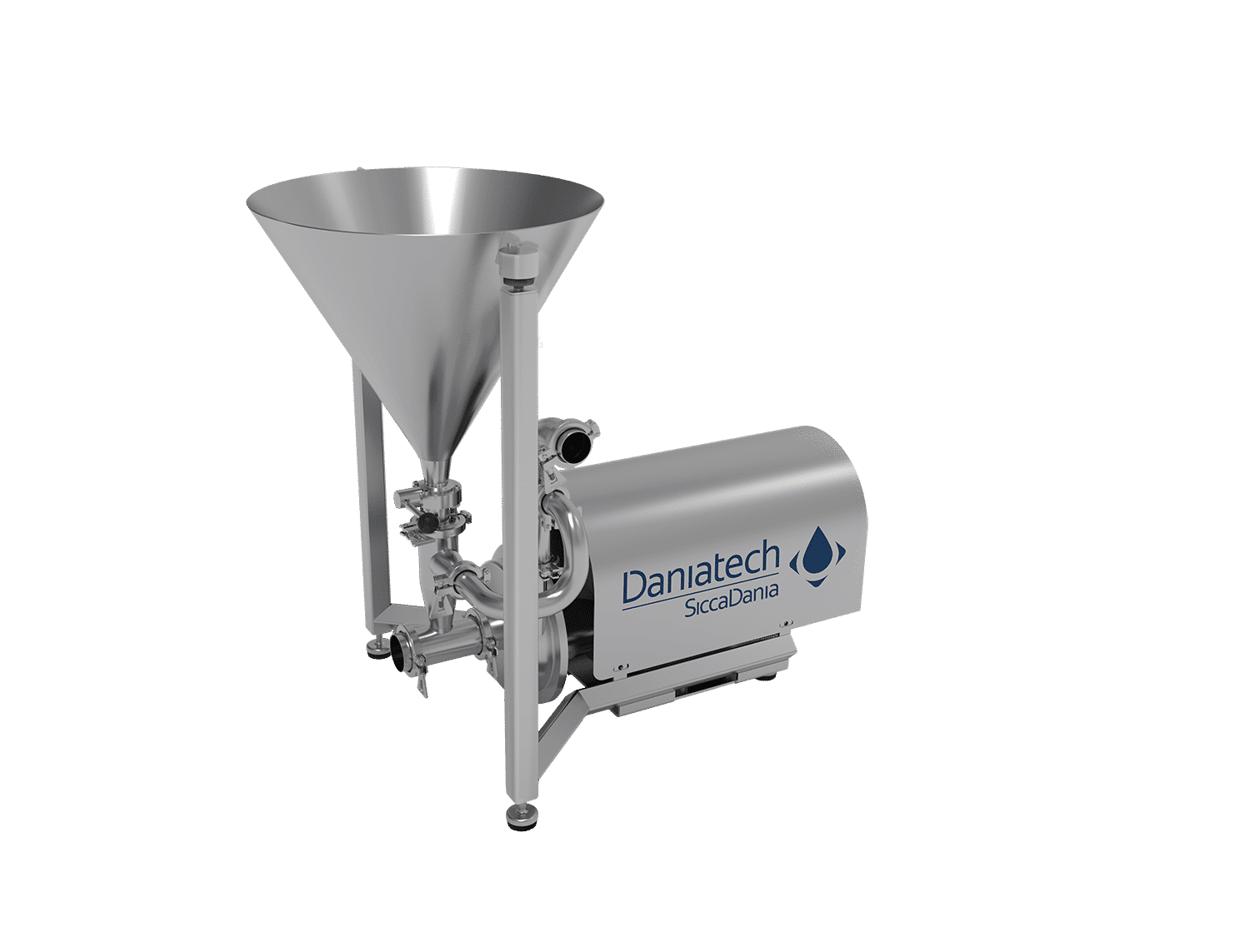

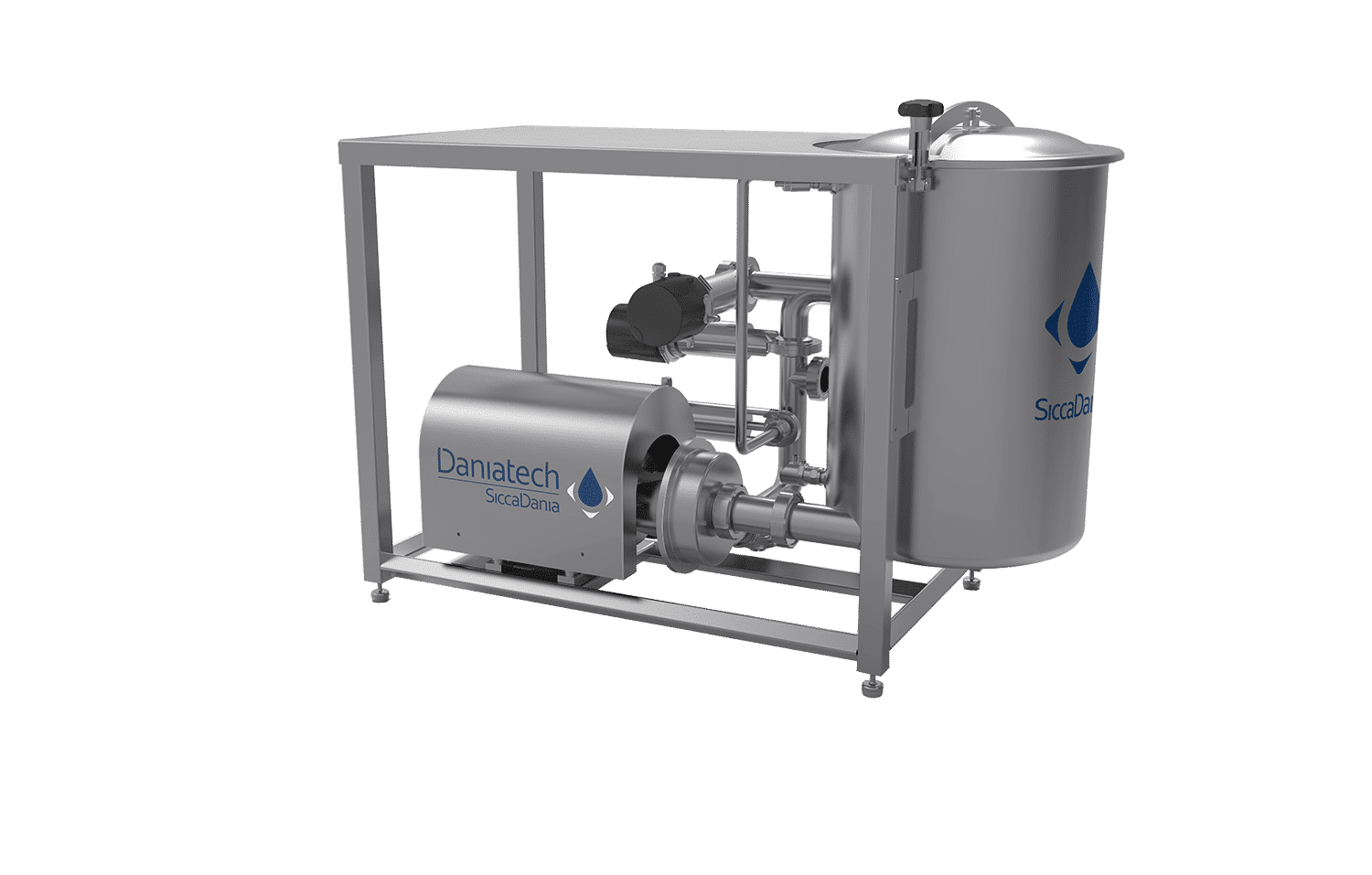

The InlineMaster is a uniquely versatile mixer designed for the quick addition of ingredients. The mixer is equipped with a vacuum feature which allows automatic handling of the powder dosing directly from big bags or silos.

By means of vacuum, the powder is drawn into the mixer below liquid level and instantly wetted. The powerful, high-shear mixer generates a controlled vortex in the tank. The combination of vortex and vacuum effectively separates air from liquid and generates a perfect homogeneous dispersion within seconds.

The result is a highly stable, homogeneous, air- and lump-free product. Due to the discharge flow/pressure of the InlineMaster, an external recirculation pump is in some cases not required.

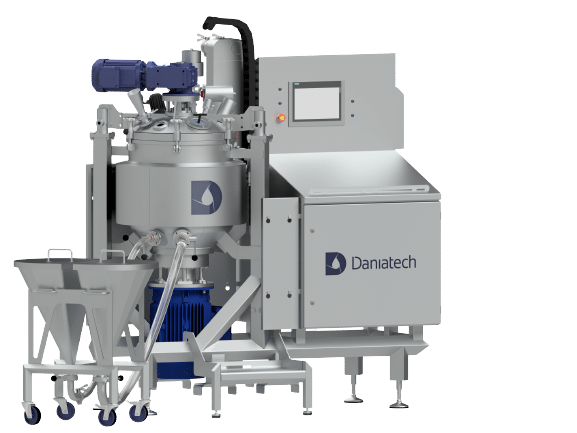

Process overview

The InlineMaster can function in a continuous flow over a buffer tank. This increases the volume and allows the InlineMaster to produce over 20.000 l/h with a powder capacity of 6.000 kg/h in an 800 l InlineMaster.

With a bigger InlineMaster, it is possible to produce over 40.000 litres of finished product pr. hour and reach a powder intake of 14.000 kg/h.

For viscosities of more than 500-700 cP with a solid content above 20%, we recommend using a batch mixer. With a batch mixer, it is possible to recirculate inside the mixer while also circulating over the buffer tank. This increases the viscosity capabilities to 1500 cP.

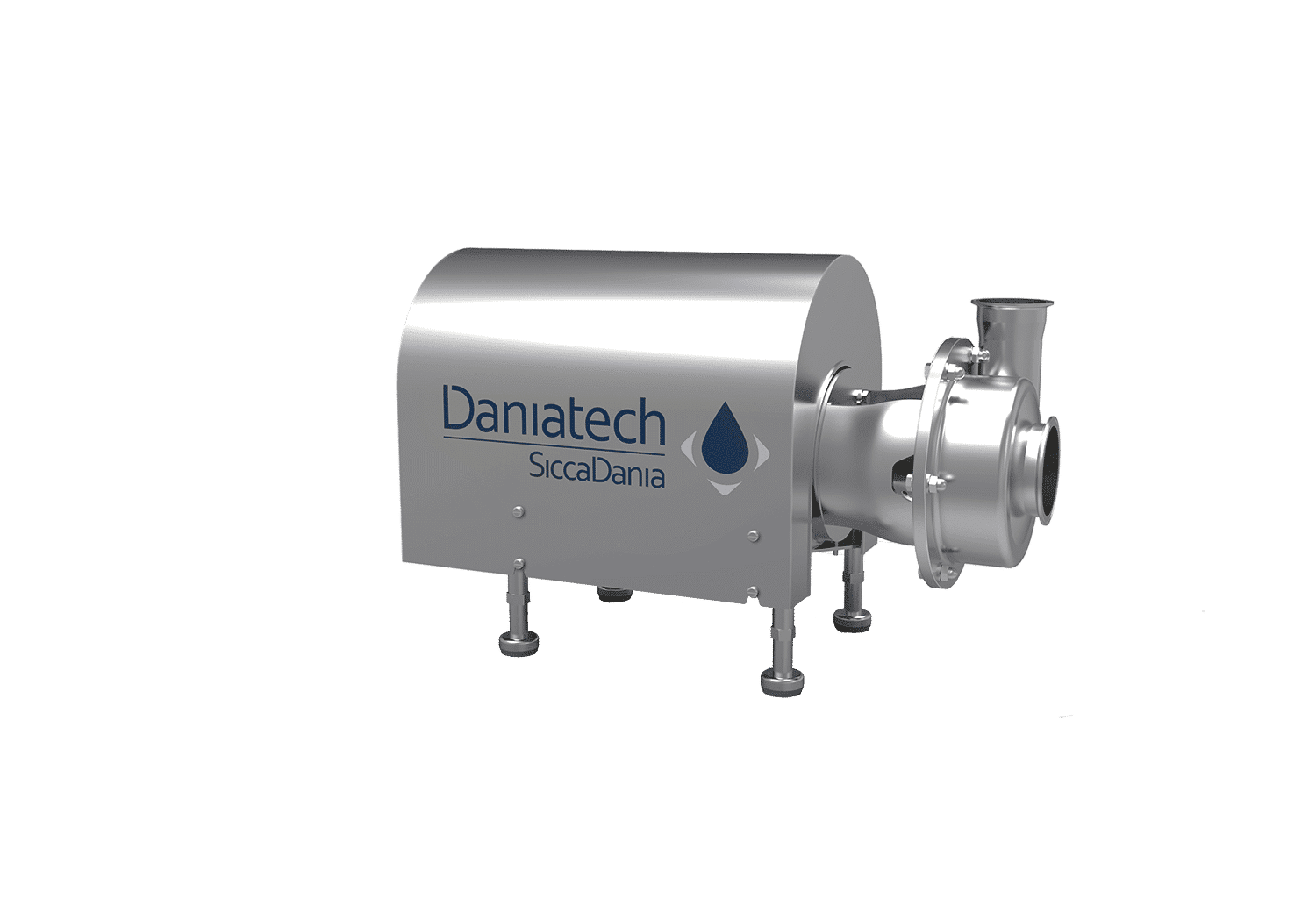

Compact, virtually maintenance-free and perfectly optimised for energy-efficient high-shear mixing.

The InlineMaster is the most energy-efficient and flexible multipurpose mixer on the market:

- Low energy consumption/high efficiency

- High shear rate

- High mixing rate

- Fast and easy installation

- Low service cost – few wear parts

- Hygienic design in compliance with EHEDG

- Step-file available on inquiry

Applications

The InlineMaster can be used for various applications e.g.:

- Products for spray drying

- Soft drinks and syrup

- Ice cream

- Sugar and pectin solutions

- Dissolving stabilisers

- Recombined milk

- Milk-based beverages

- Sweetened condensed milk*

- Recombined chocolate milk

The final product should be pumpable with a centrifugal pump – up to 1000 cP.

*Mixer size and effect on request.

Standard Equipment

- Mixer unit with flushed mechanical shaft seal (requires frequency control)

- Vacuum pump with a water-saving unit (requires frequency control)

- 3-way valve for CIP of vacuum pipe

- Cleanable vacuum system

- Manway with safety sensor

- Inspection glass with wiper/inspection glass with an LED light source

- 2 x powder valves (butterfly)

- 1 x outlet valve (butterfly)

- 2 x rotating spray balls with 3-way valve from vacuum pipe

- 2 x level sensors top & bottom

- Temperature transmitter

- Pressure sensor

- Fittings: TRI-Clams, SMS or DIN-ISO

- Built according to EHEDG

Options

- Powder hoppers (100 l, 250 l, 500 l, 1000 l & 2000 l)

- Powder hopper for small ingredients incl. butterfly valve

- Extra powder valve 2½” butterfly/extra inlet in the top

- MCC panel with inverters

- I/O Panel for connection to central control

- Outlet pump

- Load cells (2 pc global weighing) with a transmitter in a stainless steel box

- Insulated jacket

- Process valve – different types are available

- ATEX

- Other motors, NEMA, etc. on request

- 3A Design

Applications

The InlineMaster can be used for various applications e.g.:

- Products for spray drying

- Soft drinks and syrup

- Ice cream

- Sugar and pectin solutions

- Dissolving stabilisers

- Recombined milk

- Milk-based beverages

- Sweetened condensed milk*

- Recombined chocolate milk

The final product should be pumpable with a centrifugal pump – up to 1000 cP.

*Mixer size and effect on request.

| Model | Mixer size | Product density | Viscosity | Mixer effect | Powder flow rate | Vacuum volume | Discharge flow | Internal flow | Discharge pressure |

| 500 | 160 | 1-1.35 kg/l | 1-10,000 cP | 18,5-22 kW | 4-5 ton | 5.5 kW | 15-20 m3 | 80 m3/h | 1 bar |

| 1000 | 200 | 1-1.35 kg/l | 1-10,000 cP | 22-30 kW | 5-8 ton | 7.5 kW | 20-30 m3 | 220 m3/h | 1 bar |

| 2000 | 250 | 1-1.35 kg/l | 1-10,000 cP | 45-55 kW | 8-10 ton | 11 kW | 30-50 m3 | 350 m3/h | 1 bar |

| 3000 | 325 | 1-1.35 kg/l | 1-10,000 cP | 55-75 kW | 10-12 ton | 11 kW | 50-75 m3 | 500 m3/h | 1 bar |

| Model | Outlet/U | Powder valve | CIP | Inlet | Service water | Dimensions (H x W x D) | Shipping weight | Shipping volume |

| 500 | Ø51/650 mm | 1 x Ø51 1 x Ø63.5 |

Ø51 | 1x Ø51 | 100 L/h | 2400 x 1300 x 1000 mm | 900 kg | 3.4 m3 |

| 1000 | Ø63,5/650 mm | 1 x Ø51 1 x Ø63.5 |

Ø51 | 1x Ø51 | 100 L/h | 3400 x 1400 x 1200 mm | 1400 kg | 5.7 m3 |

| 2000 | Ø76/1000 mm | 2 x Ø63.5 | Ø51 | 2x Ø51 | 100 L/h | 3800 x 2000 x 1700 mm | 1800 kg | 13 m3 |

| 3000 | Ø101.7/1200 mm | 2 x Ø63.5 | Ø51 | 2x Ø51 | 150 L/h | 4300 x 2500 x 2000 mm | 2200 kg | 21.5 m3 |