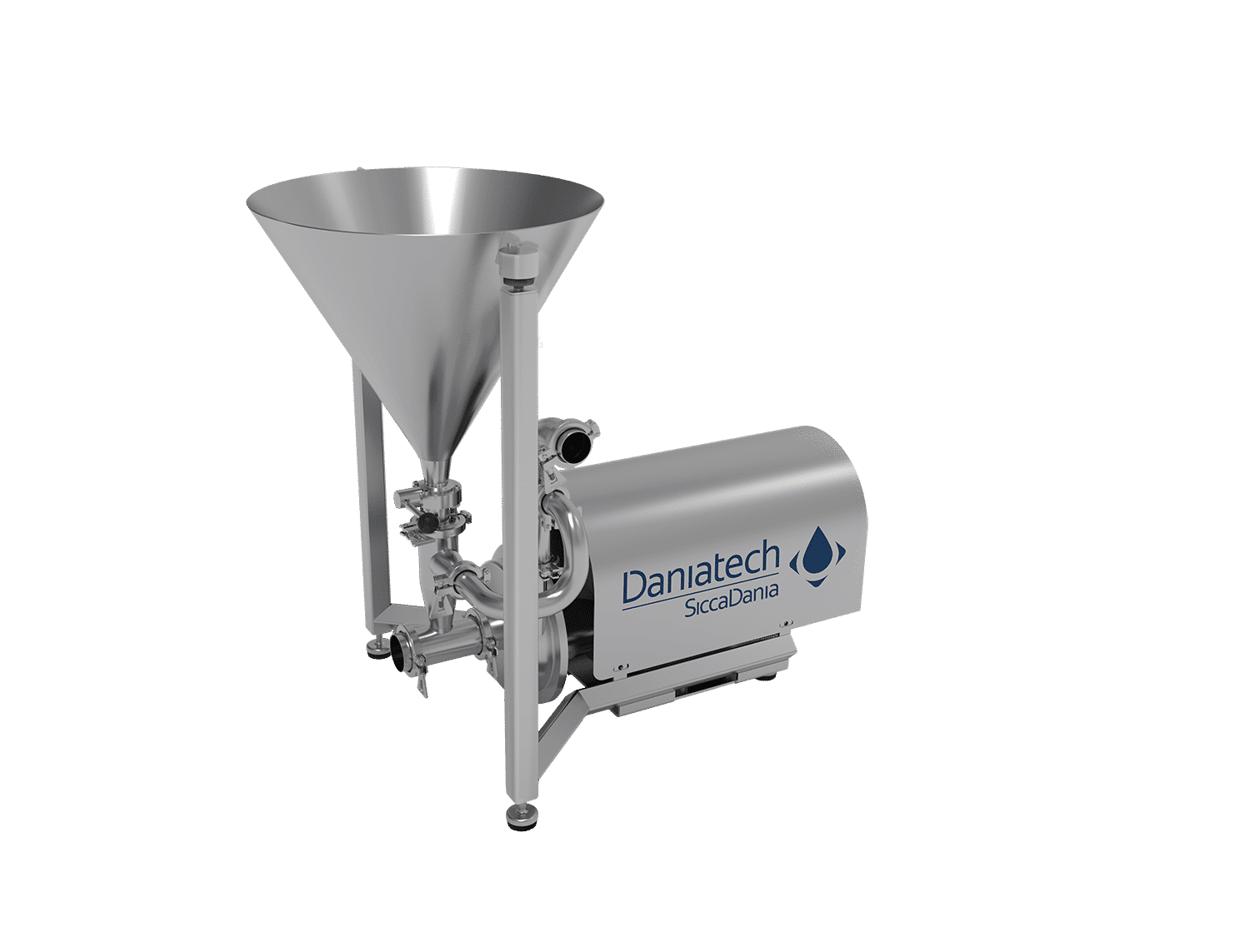

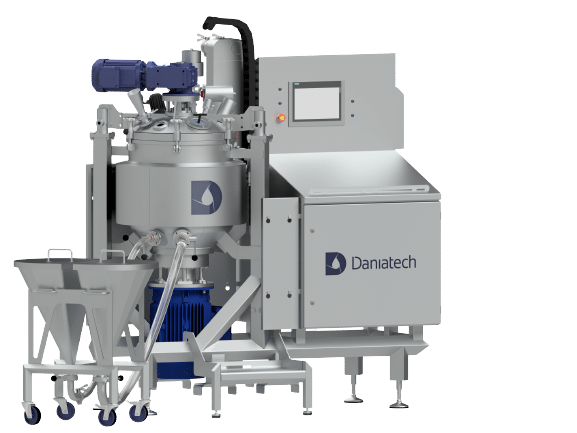

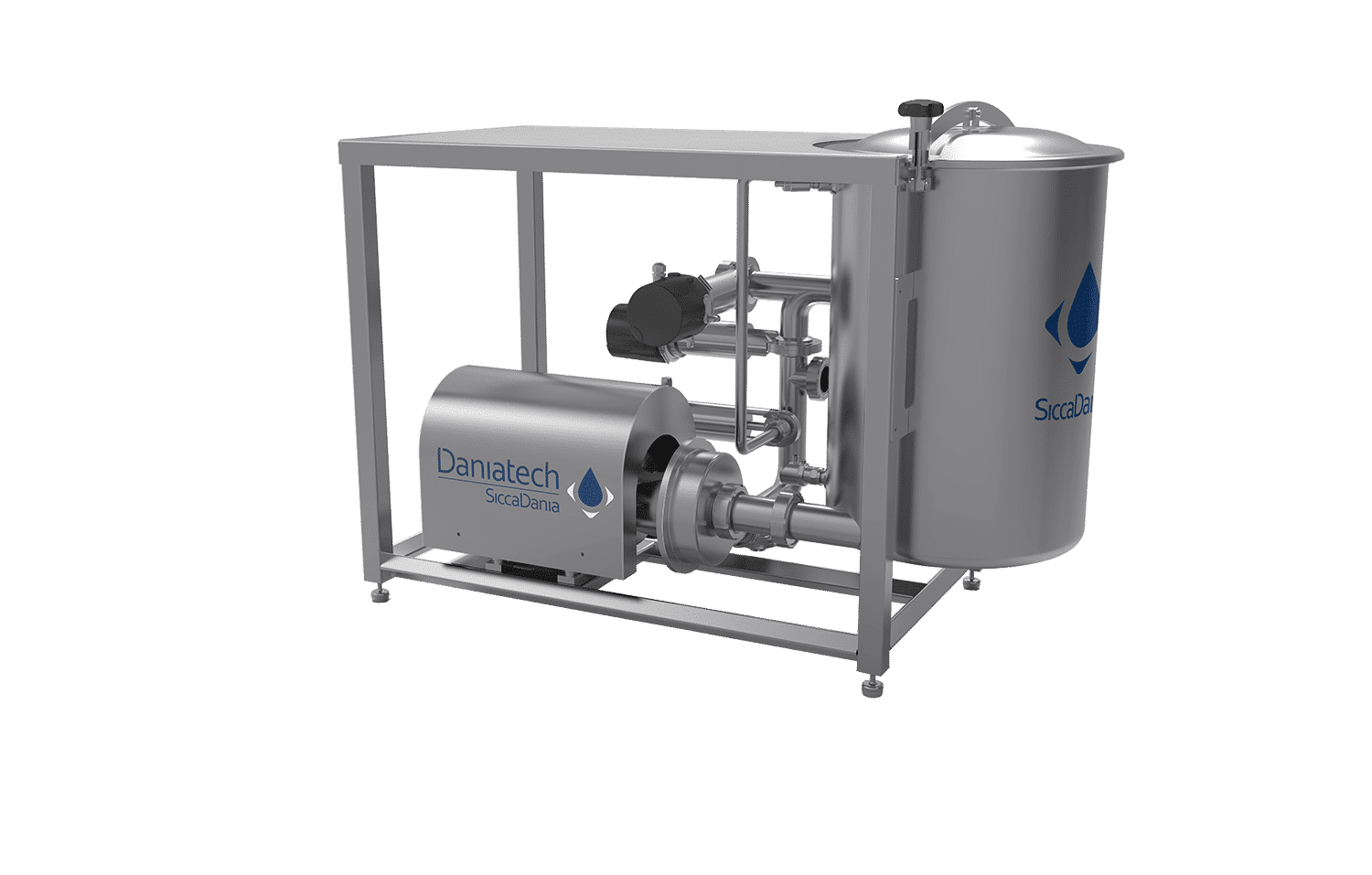

The BasicMaster represents the newer and more energy-efficient generation of mixing solutions for the process industry.

The BasicMaster is a manually operated mixer with a minimum of automated control. The powder is added manually through the manway and is instantly incorporated into the liquid. The mixer generates a controlled vortex in the tank, which contributes to separating air from the liquid generating a perfect homogeneous dispersion within seconds.

The result is a highly stable and homogeneous product, which is lump-free and contains a minimum of air.

The BasicMaster is compact and perfectly optimised for energy-efficient high-shear mixing. Customers will benefit from a mixer that is virtually maintenance-free.

Depending on the selected options (which can be found in the tab Equipment), the mixer can be used as a batch mixer or an in-line mixer. For in-line mixing, a circulation loop is required.

Applications

Customers will be able to create a wide range of products, e.g.:

- Products for spray drying

- Soft drinks

- Ice cream

- Sugar solutions

- Dissolving stabilisers

- Syrup

- Slurries

- Soups

- Recombined milk-based products

- Etc.

(The final product must be pumpable using a standard centrifugal pump – viscosity up to 2000 cP. For viscosity above 2000 cP, it is required to choose a ProcessMaster)

Standard Equipment

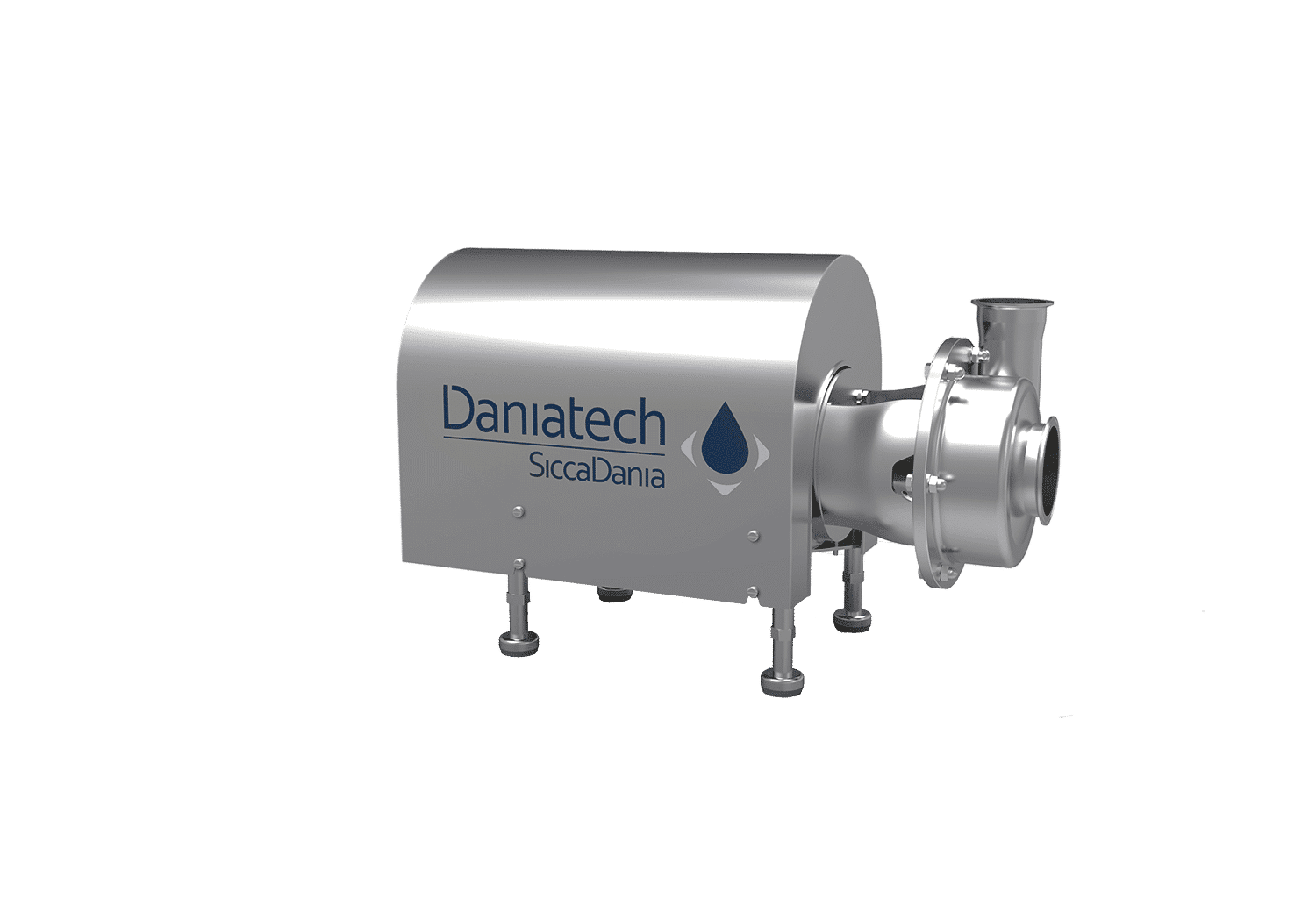

- Mixer unit with flushed mechanical shaft seal (requires frequency control)

- Manway with safety net and safety switch

- 1 x outlet valve (butterfly)

- 1 x liquid inlet

- 2 x rotating spray balls

- 2 x level sensors – top & bottom

- Fittings: TRI-Clamps, SMS or DIN-ISO

- Hygienic design in compliance with EHEDG

Options

- Extra top inlet/sampling

- Sack delivery chute

- Level control pressure transmitter/control valve with tangential side admission

- Load cells with the transmitter in a stainless steel box

- Outlet pump (must be equipped with frequency converter, if used as inline mixer)

- MCC panel with frequency inverters

- Insulated jacket

- ATEX

- Other motors, NEMA, etc. on request

Applications

Customers will be able to create a wide range of products, e.g.:

- Products for spray drying

- Soft drinks

- Ice cream

- Sugar solutions

- Dissolving stabilisers

- Syrup

- Slurries

- Soups

- Recombined milk-based products

- Etc.

(The final product must be pumpable using a standard centrifugal pump – viscosity up to 2000 cP. For viscosity above 2000 cP, it is required to choose a ProcessMaster)

| Model | Product density | Viscosity | Mixer effect | Powder capacity |

| 250 | 1-1.35 kg/l | 1-2000 cP | 11-18.5 kW | 50 kg/min |

| 500 | 1-1.35 kg/l | 1-2000 cP | 18.5 – 22 kW | 50 kg/min |

| 1000 | 1-1.35 kg/l | 1-2000 cP | 22-30 kW | 100 kg/min |

| 2000 | 1-1.35 kg/l | 1-2000 cP | 45-55 kW | 100 -150 kg/min |

| 3000 | 1-1.35 kg/l | 1-2000 cP | 55-75 kW | 200 kg/min |

| 5000 | 1-1.35 kg/l | 1-2000 cP | 75-90 kW | 300 kg/min |

Powder capacity is based on sugar or standard milk-based powders.

| Model | Outlet/U | CIP | Inlet | Dimensions (H x W x D) | Shipping weight | Shipping volume |

| 250 | Ø51/650 mm | Ø51 | 1x Ø51 | 2200 x 1200 x 900 mm | 500 kg | 2 m3 |

| 500 | Ø51/650 mm | Ø51 | 1x Ø51 | 2400 x 1300 x 1000 mm | 700 kg | 2.5 m3 |

| 1000 | Ø63.5/650 mm | Ø51 | 1x Ø51 | 3400 x 1400 x 1200 mm | 1000 kg | 2.5 m3 |

| 2000 | Ø63.5/1000 mm | Ø51 | 1x Ø51 | 3800 x 2000 x 1700 mm | 1400 kg | 10.5 m3 |

| 3000 | Ø76/1200 mm | Ø51 | 1x Ø51 | 4300 x 2500 x 2000 mm | 1600 kg | 16.5 m3 |

| 5000 | Ø76/1200 mm | Ø51 | 1x Ø51 | 4600 x 2600 x 2200 mm | 1700 kg | 21 m3 |