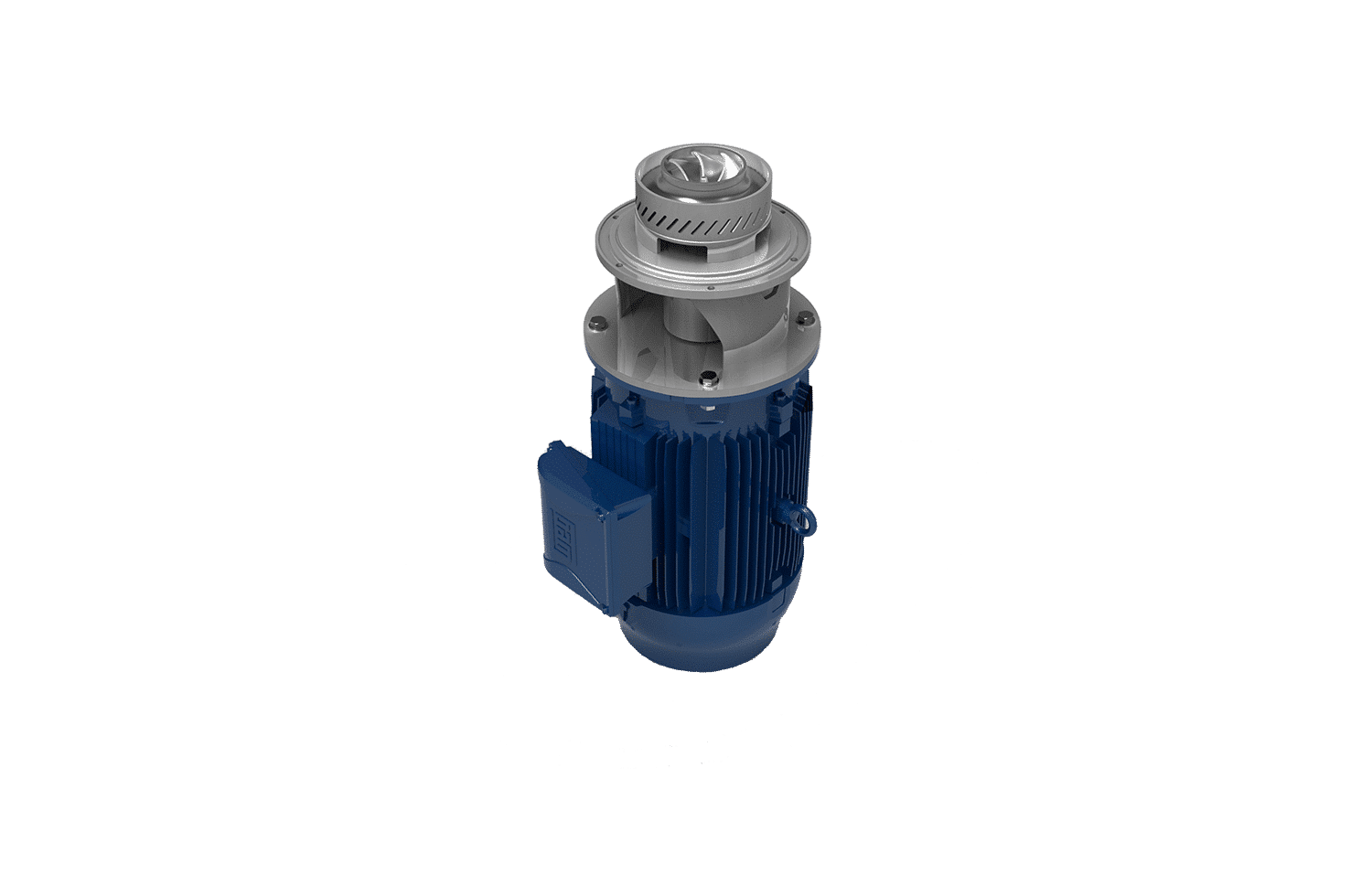

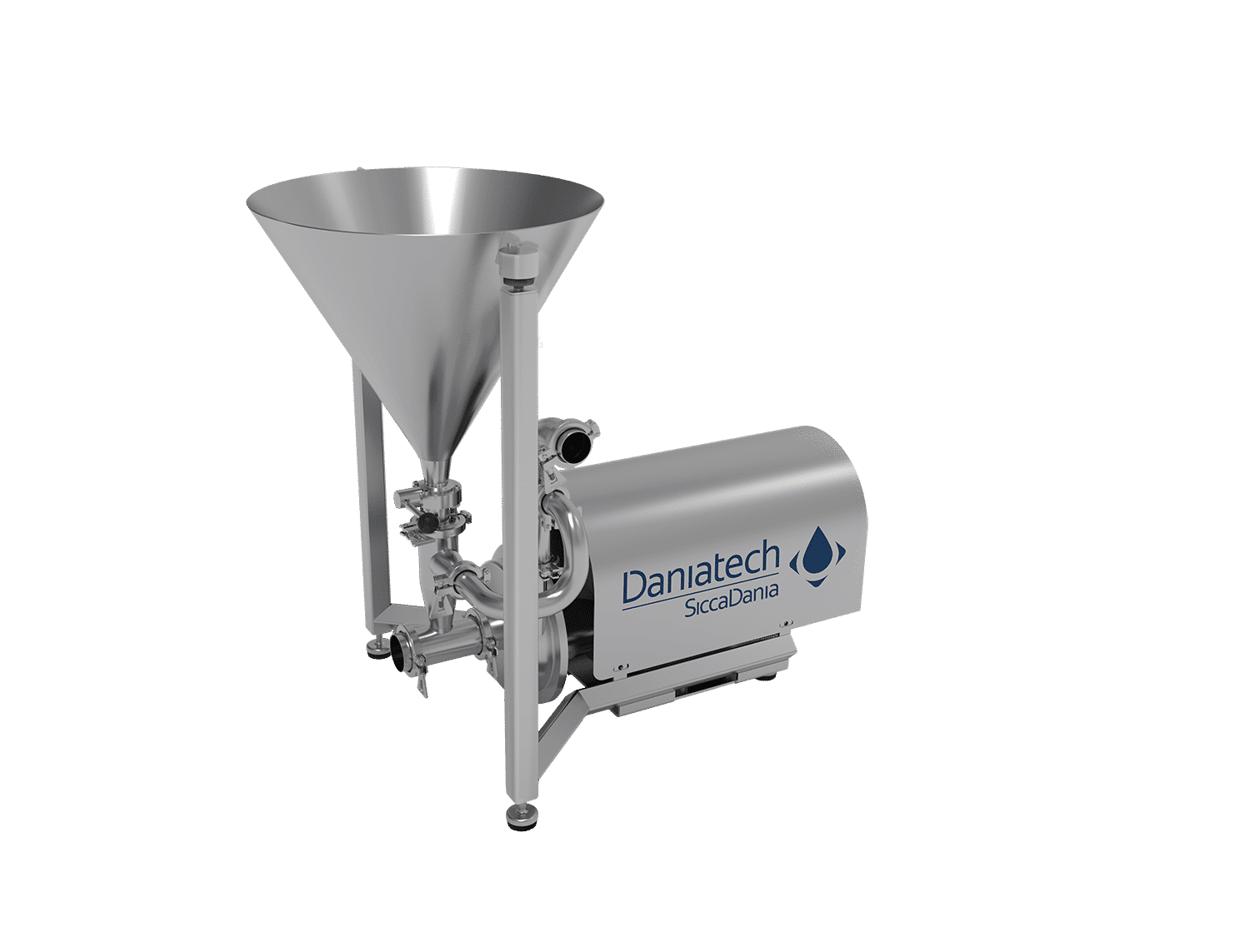

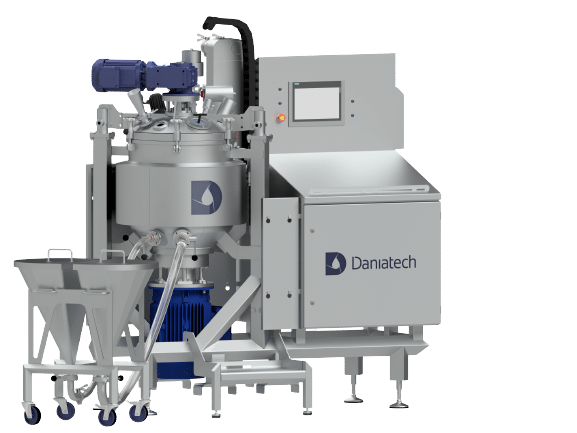

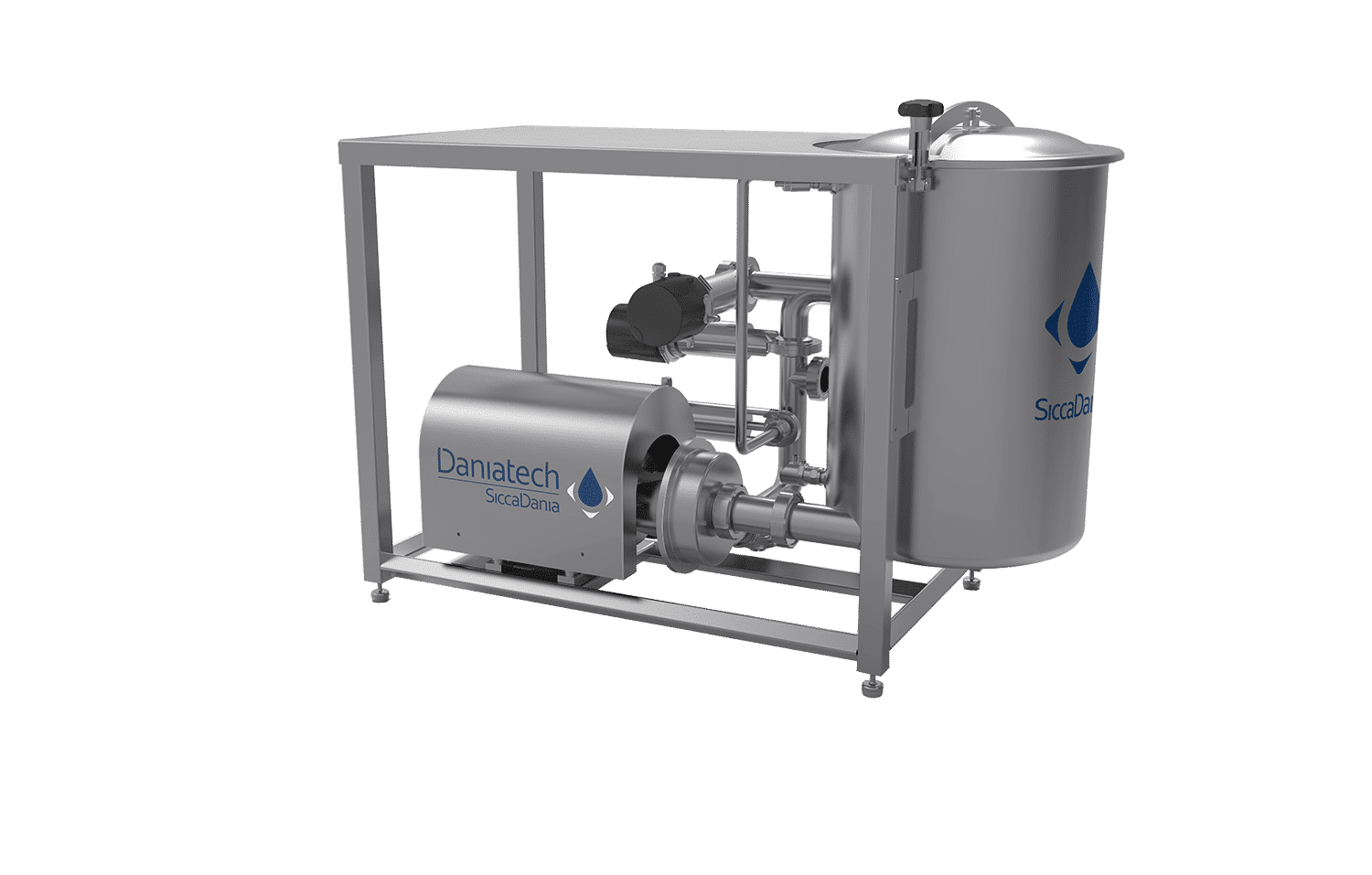

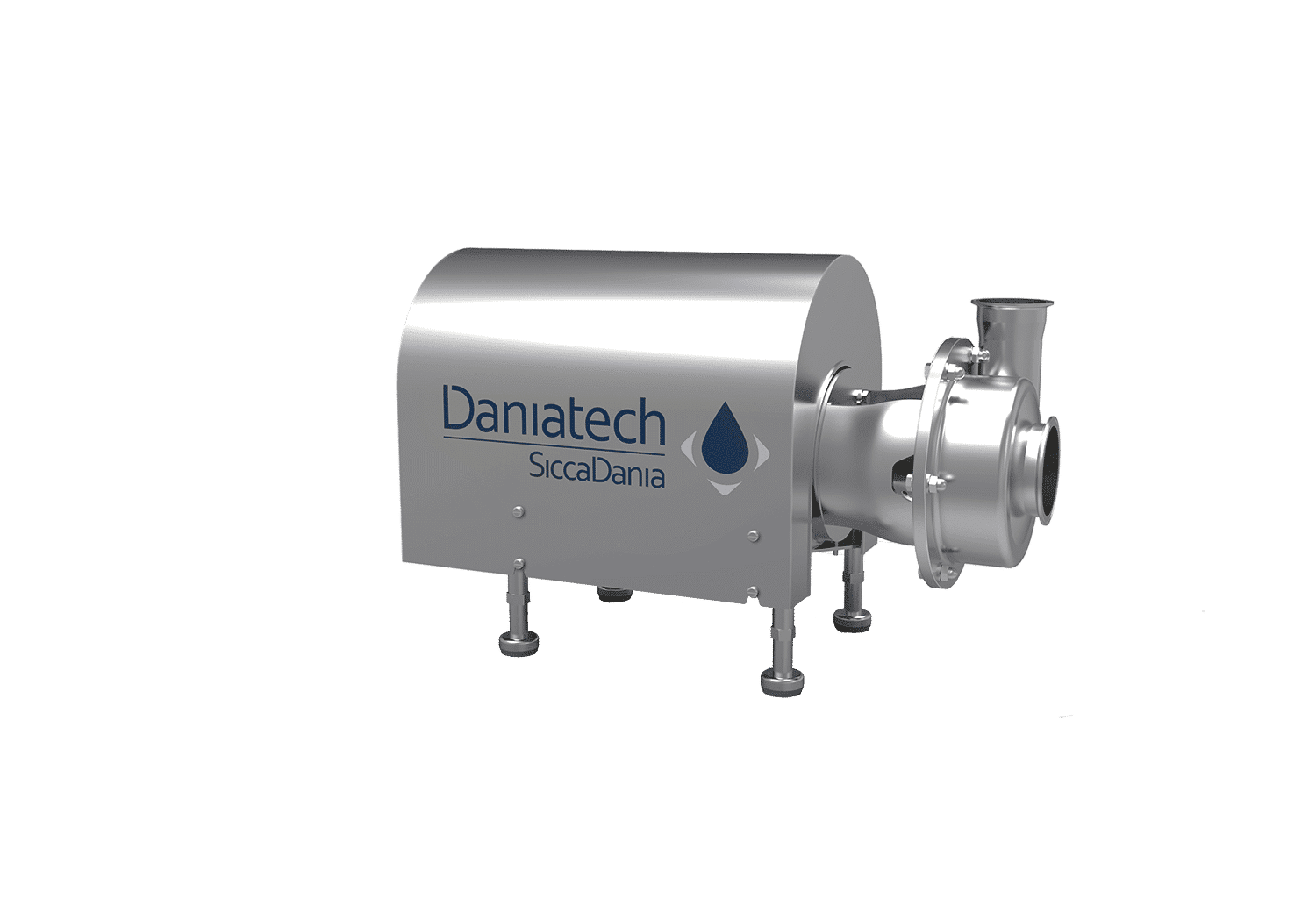

The ShearMaster is a compact and perfectly optimised energy-efficient high shear mixer. The mixer unit is designed to be welded onto existing or new tanks, where better and more efficient mixing is needed. The ShearMaster is welded into the bottom or side of the tank. It is also possible to install more units onto the silo tanks.

With the integrated, direct driven ShearMaster, customers can experience several benefits; 20% less energy compared to more conventional mixing technologies, a minimum number of spare parts and maximum noise level to approx. 75dB.

Applications

The ShearMaster has been optimised for mixing of a wide range of products, e.g.:

- Products for spray drying

- Soft drinks

- Ice cream

- Sugar solutions

- Pectin solutions

- Syrup

- Slurries

- Soups

- Pet-food Gravy

- Recombined milk-based products

Depending on the type of viscosity (Shear sensitive e.g. Ketchup) products with up to 5000 cP can be processed.

Standard Equipment

- Mixer unit (230/400V 50Hz) with shaft sealing (to be frequency controlled)

- Welding Flange

- O-Ring EPDM

- Shaft seal carbon/SIC bellow

Standard on ShearMaster 80-160:

- Double mechanical shaft seal with solenoid valve and throttle valve

Options

- Other motors, NEMA & etc. on request.

- Propeller for extra turbulence

- Start/stop box with soft starter

- Start/stop box with frequency inverter

- Shaft seal SIC/SIC

- Sterile balance shaft seal Carbon/SIC

- Sterile balance shaft seal SIC/SIC

Applications

The ShearMaster has been optimised for mixing of a wide range of products, e.g.:

- Products for spray drying

- Soft drinks

- Ice cream

- Sugar solutions

- Pectin solutions

- Syrup

- Slurries

- Soups

- Pet-food Gravy

- Recombined milk-based products

Depending on the type of viscosity (Shear sensitive e.g. Ketchup) products with up to 5000 cP can be processed.

| Model | Motor | Flow | Shear Rate | Recommended Tank Size |

| ShearMaster 65-125 | 5,5 kW | 50 – 70 m³ | 18-35000 s-1 | 50 – 100 l |

| ShearMaster 65-125 | 7,5 kW | 60 – 80 m³ | 18-35000 s-1 | 75 – 150 l |

| ShearMaster 80-160 | 11 kW | 80 – 120 m³ | 25-50000 s-1 | 200 – 400 l |

| ShearMaster 80-160 | 15 kW | 100-130 m³ | 25-50000 s-1 | 300 – 600 l |

| Model | Flange Diameter | Service Water* | Weight | Dimensions (L x D) |

| ShearMaster 65-125 | 220 mm | N/X | 65 kg | 550 x 225 mm |

| ShearMaster 65-125 | 220 mm | N/A | 67 kg | 600 x 240 mm |

| ShearMaster 80-160 | 310 mm | 20 l/h | 100 kg | 660 x 260 mm |

| ShearMaster 80-160 | 310 mm | 20 l/h | 110 kg | 700 x 280 mm |