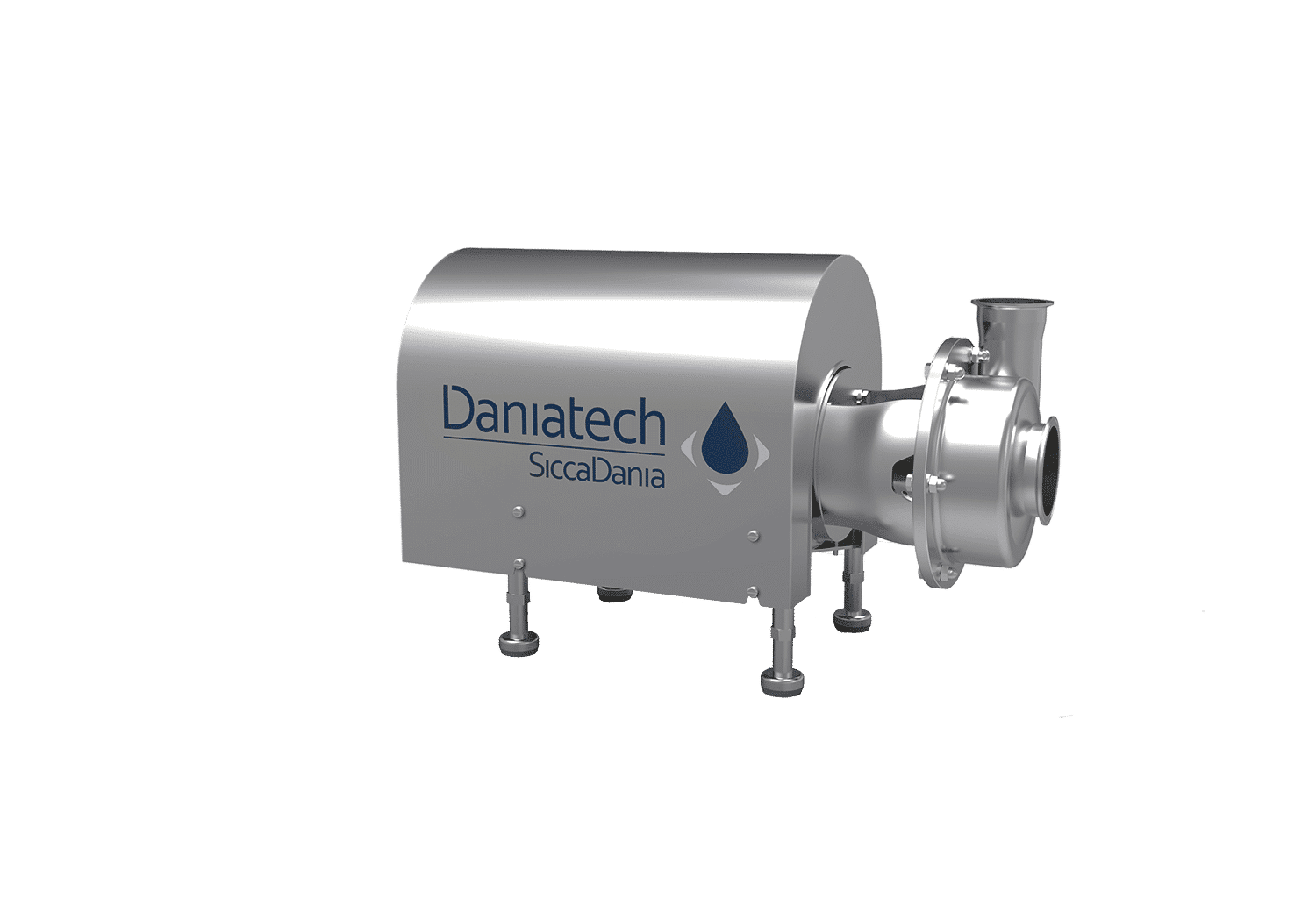

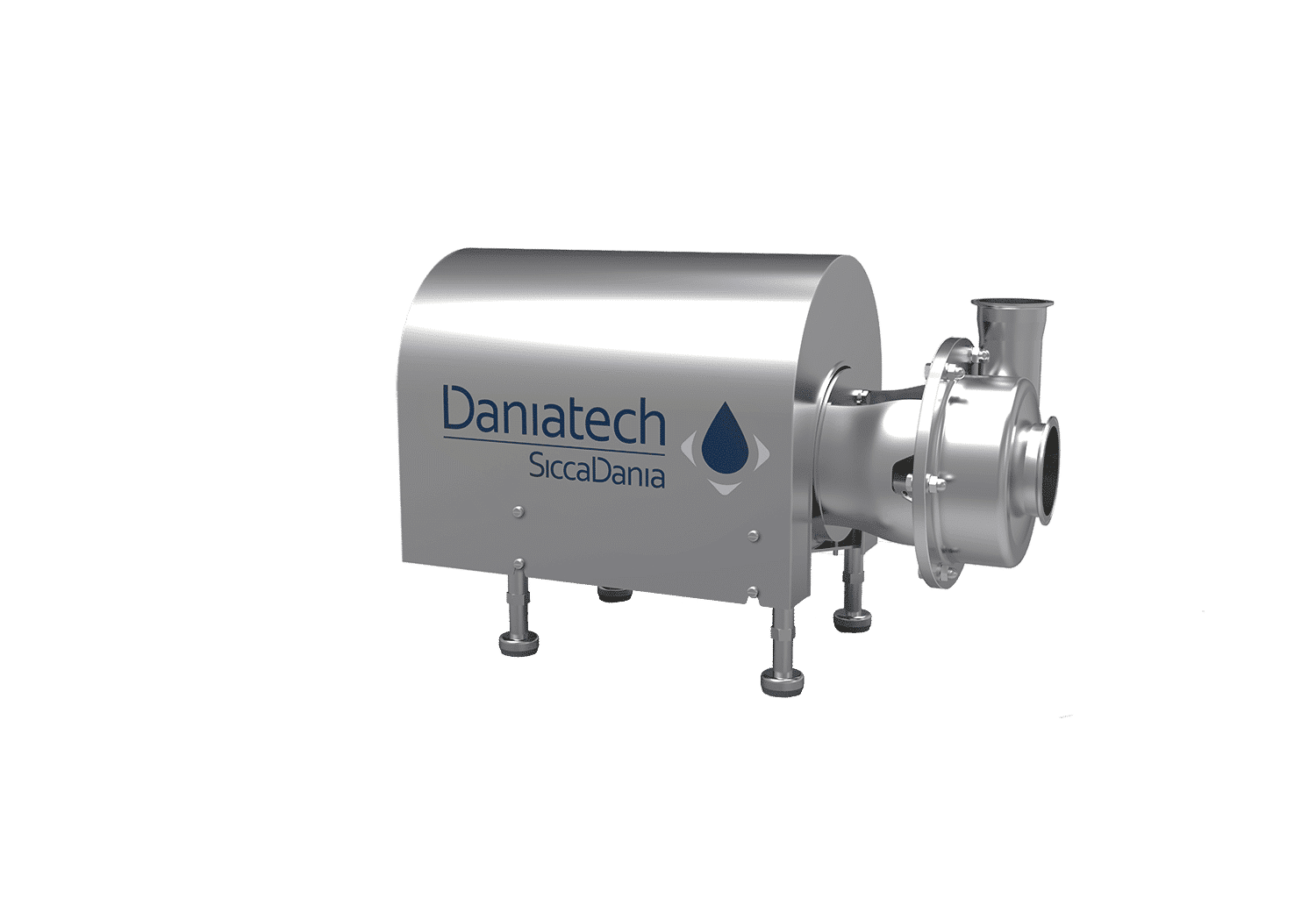

The MixMaster is a versatile, compact solution for inline high shear mixing. The mixer works according to the rotor-stator principle, where a special closed mixing wheel passes the product through patented slots.

The MixMaster unit is very versatile and can be used in many setups and applications.

- For low to medium viscosity products, the mixer performs the out-pumping action itself.

- For high-viscose applications (>250cP) the setup requires positive feeding.

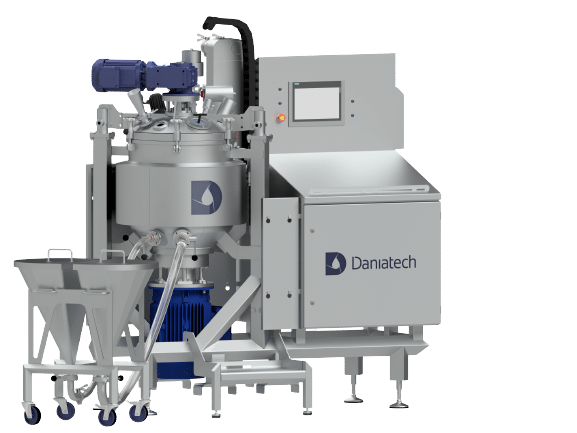

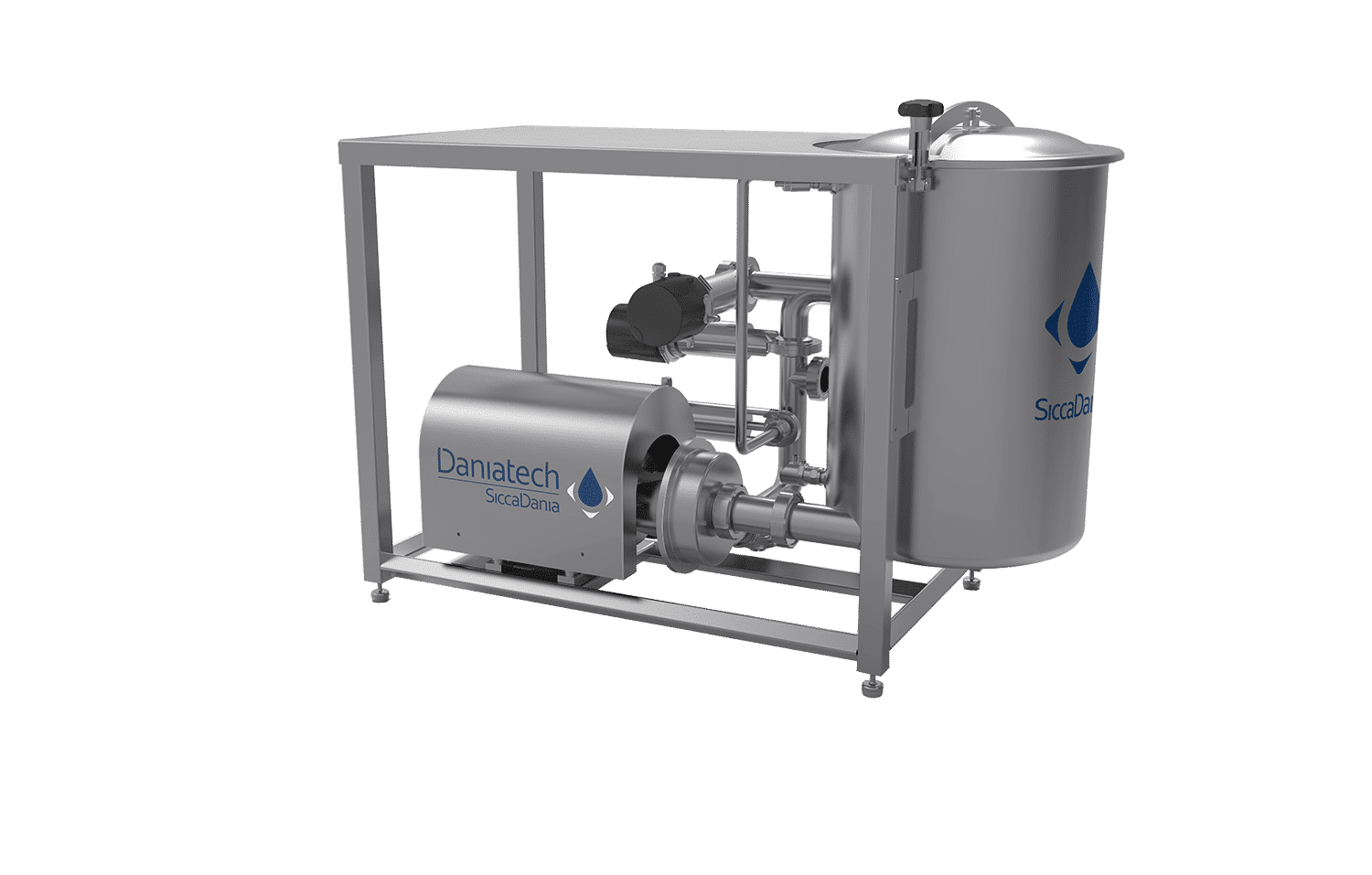

The mixing unit from Daniatech provides customers with an effective high-shear mixing pump. This unit offers two different types of operation:

- Batch operation – the mixer is placed in a circulation loop over a process vessel

- Inline setup – the mixer is placed between two process vessels and operates in a single pass.

For some applications, the mixer adds light homogenisation.

Applications

SiccaDania MixMaster is a small unit perfect for applications, such as:

- Emulsion

- Droplet size-reduction

- Slurries

- Concentrates (Liquid/Liquid)

- Pigment solution

- Smoothening of yoghurt

- Viscosity reduction of yoghurt

- Fish-eye removal in soft drinks/Stabiliser solutions

- Blending Applications

Homogenisation down to 2μ lump-free

Standard Equipment

- Mixer unit with flushed mechanical shaft seal (requires frequency control)

- Tri-clamp inlet/outlet

- Motor Cover

- Frame with 4 legs

Options

- Double mechanical shaft seal with solenoid valve and throttle valve

- Bypass loop for extra circulation over the mixer

- Fitting SMS DIN/ISO. Other on request

- Other motors, NEMA & etc. on request.

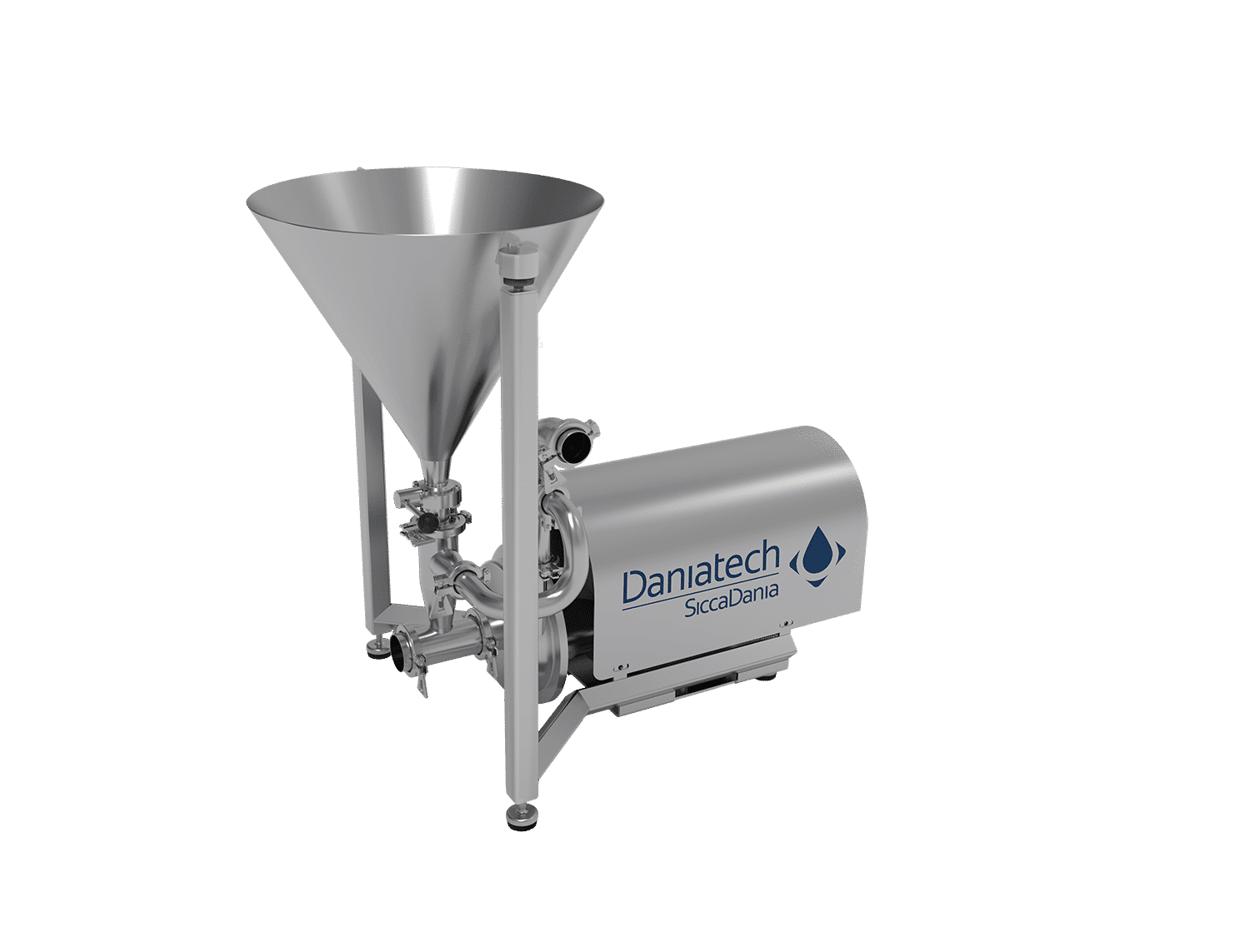

- Injector for powder intake with 100-litre funnel (see InjectMaster)

- Start/stop box with soft starter

- Start/stop box with frequency inverter

Applications

SiccaDania MixMaster is a small unit perfect for applications, such as:

- Emulsion

- Droplet size-reduction

- Slurries

- Concentrates (Liquid/Liquid)

- Pigment solution

- Smoothening of yoghurt

- Viscosity reduction of yoghurt

- Fish-eye removal in soft drinks/Stabiliser solutions

- Blending Applications

Homogenisation down to 2μ lump-free

| Model | Motor | Flow | Mixer capacity | Inlet pressure |

| MixMaster 32 – 160 | 5.5 kW | 25 (2 Bar) ms/h | 5 ms/h | 0.5 – 5 Bar |

| MixMaster 50 – 160 | 7.5 kW | 30 (2 Bar) ms/h | 7.5 ms/h | 0.5 – 5 Bar |

| MixMaster 80 – 160 | 11 kW | 40 (2 Bar) ms/h | 10 ms/h | 0.5 – 5 Bar |

| MixMaster 100 – 200 | 30kW | 90 (4 Bar) ms/h | 25 ms/h | 0.5 – 5 Bar |

| MixMaster 100 – 200 | 45 kW | 125 (4 Bar) ms/h | 30 ms/h | 0.5 – 5 Bar |

| Model | Outlet pressure | Service Water* | Weight | Dimensions (H x W x D) |

| MixMaster 32 – 160 | 2.5 – 7 Bar | 20 l/h | 75 kg | 650 x 420 x 930 mm |

| MixMaster 50 – 160 | 2.5 – 7 Bar | 20 l/h | 75 kg | 500 x 420 x 930 mm |

| MixMaster 80 – 160 | 2.5 – 7 Bar | 20 l/h | 80 kg | 650 x 420 x 930 mm |

| MixMaster 100 – 200 | 2.5 – 8 Bar | 20 l/h | 110 kg | 908 x 460 x 930 mm |

| MixMaster 100 – 200 | 2.5 – 8 Bar | 20 l/h | 150 kg | 908 x 680 x 1150 mmm |