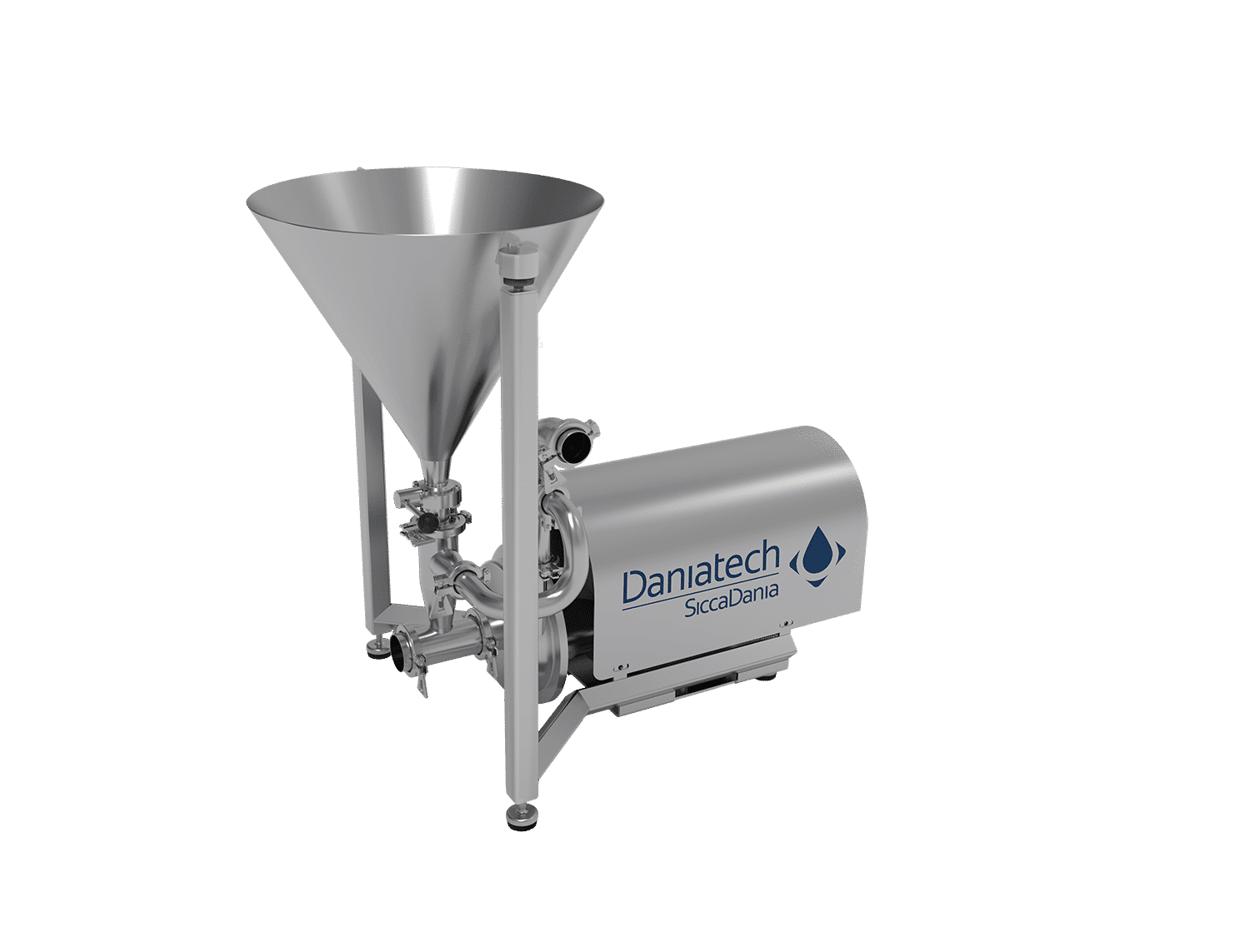

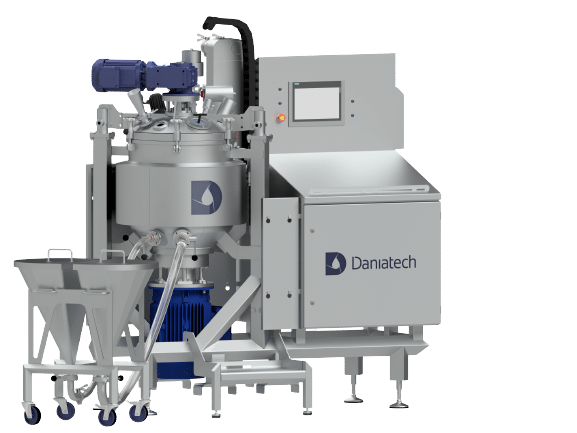

The InjectMaster is designed with an innovative injector that creates a strong suction of powder. The mixer works according to the rotor-stator principle, where a uniquely designed mixing wheel passes the product through patented slots.

During operation, the mixing wheel accelerates the liquid and creates pressure in the injector pipe, which draws the powder from the powder funnel. The amount of powder is controlled by a manual butterfly valve.

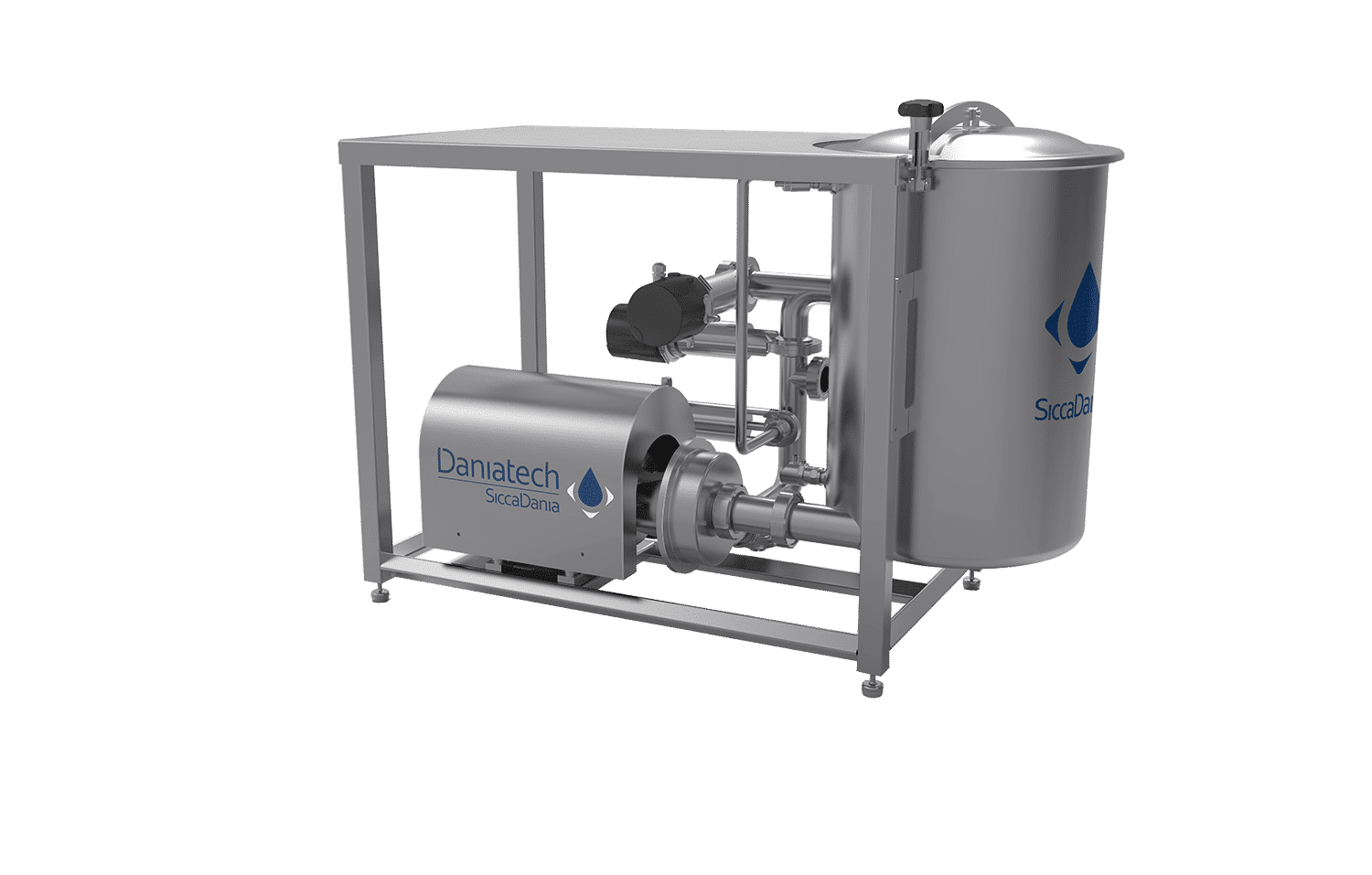

The mixer unit is versatile and can be used in many setups and applications. For low to medium viscosity products, the mixer performs the pumping action itself.

For high-viscose applications (>500 cP) the setup requires positive feeding. The mixer system can be integrated into a table that offers an ergonomic working position.

With the InjectMaster, our customers receive a mixer with:

- Ergonomic working height

- Low energy/high efficiency

- Strong shear rate

- Low service cost

- Designed according to EHEDG

- Step-file available on request

Applications

The InjectMaster can be used for various applications e.g.:

- Powder and Liquids

- Sugar Solutions

- Recombined dairy products

- Brine

Homogenisation down to 2μ lump-free.

Standard Equipment

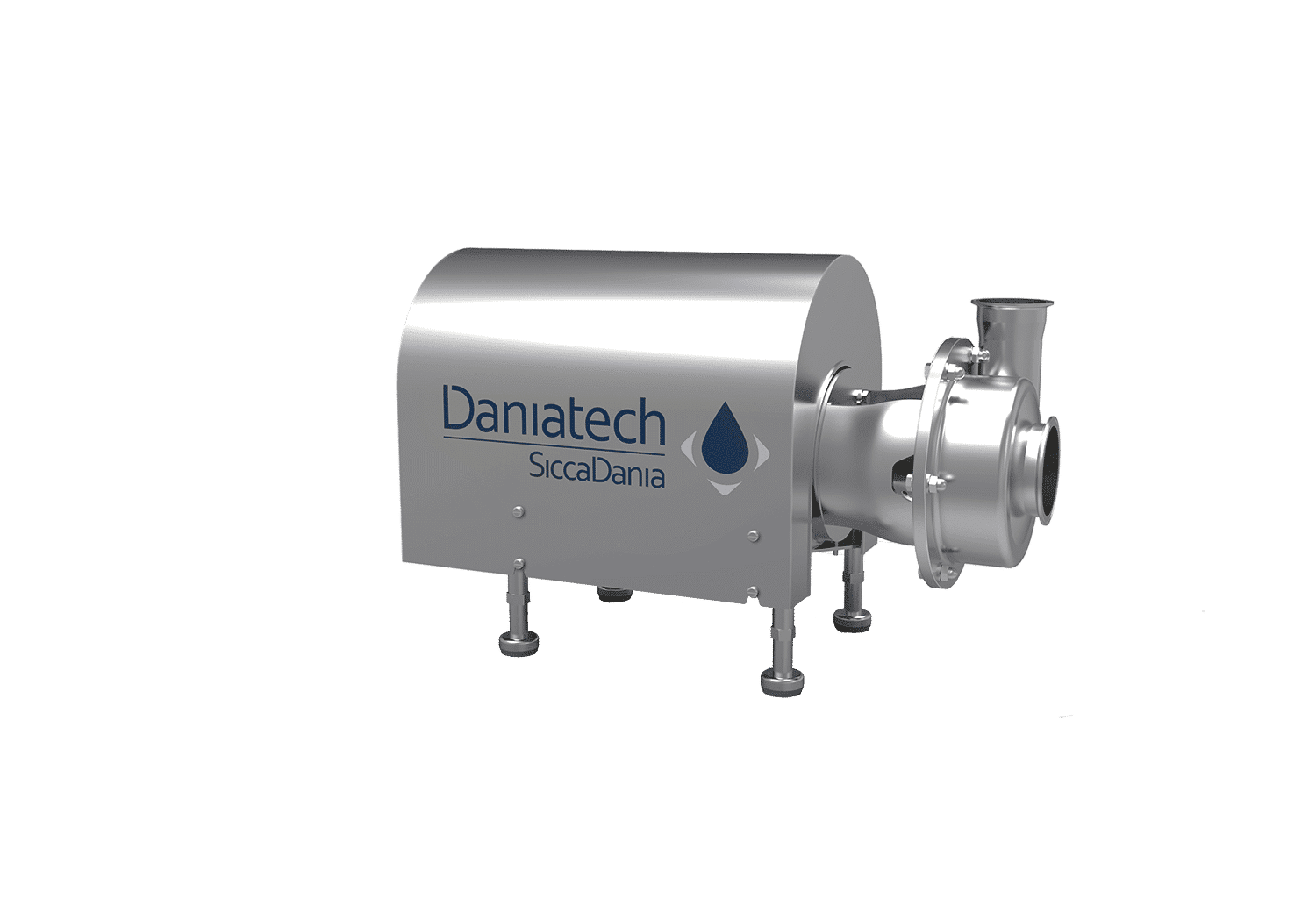

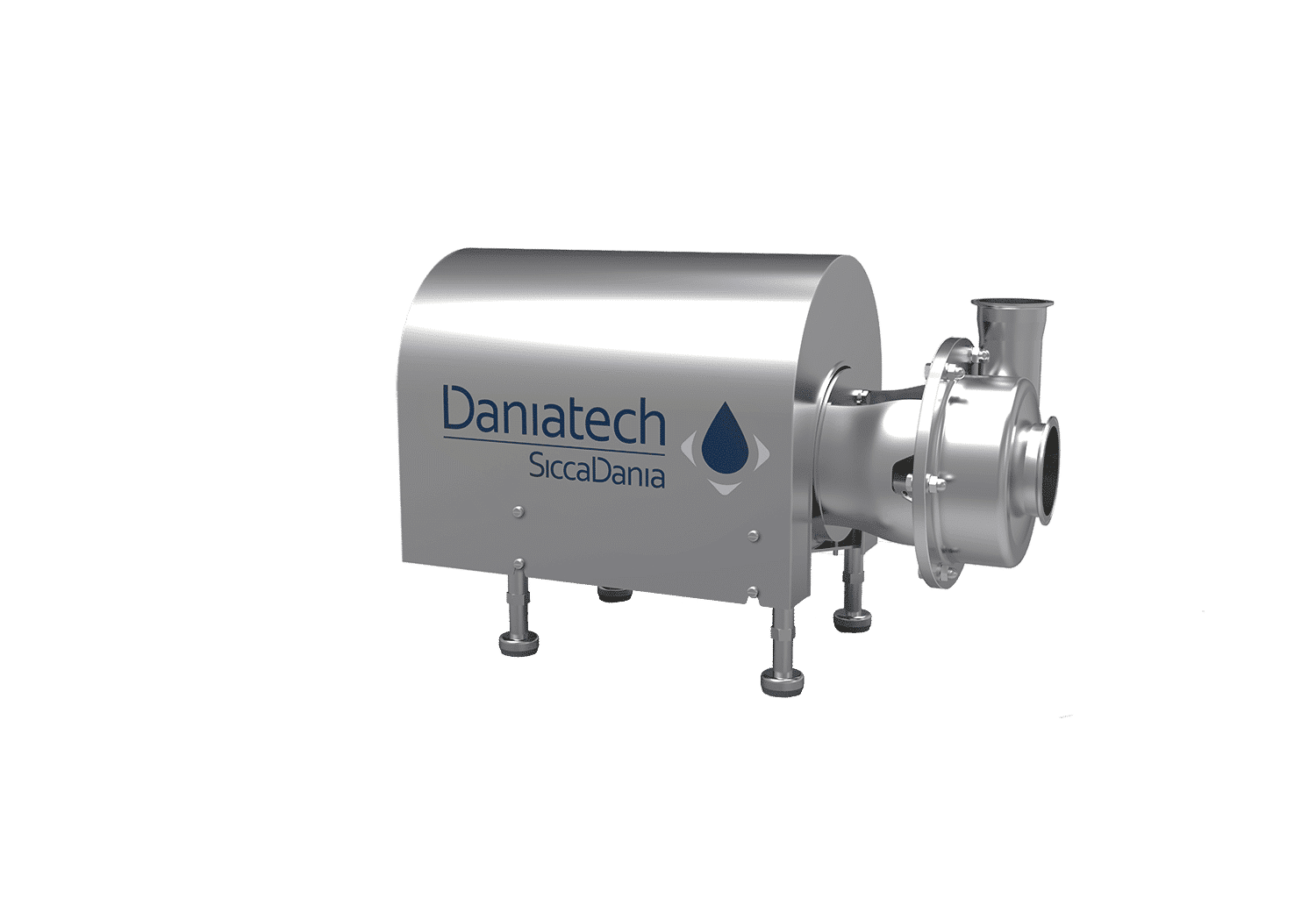

- Mixer unit (230/400 V 50 Hz) with single shaft seal

- Tri-clamp inlet/outlet

Options

- Double mechanical shaft seal with Bürkert (1/8″) solenoid valve and throttle valve

- Powder automation – vibrator, level switch, actuator

- Control cabinet with frequency inverter

- Control cabinet with frequency inverter and powder automation

- Fittings: SMS, DIN/ISO. Other on request

- ATEX

- Other motors, NEMA exx, etc. on request

- Ergonomic working station

Applications

The InjectMaster can be used for various applications e.g.:

- Powder and Liquids

- Sugar Solutions

- Recombined dairy products

- Brine

Homogenisation down to 2μ lump-free.

| Model | Motor | Flow | Powder Capacity* | Outlet pressure |

| InjectMaster 40-160 | 5.5 kW | 25 m3/h | 40 kg/min | 2 bar |

| InjectMaster 50-160 | 7.5 kW | 40 m3/h | 60 kg/min | 2 bar |

*Powder capacity based on standard milk-based powders

| Model | Connection | Service Water** | Weight | Dimensions (H x W x D) | Funnel size |

| InjectMaster 40-160 | IN 2” OUT 2” | 20 l/h | 110 kg | 915 x 660 x 1100 mm | 30 l |

| InjectMaster 50-160 | IN 2½” OUT 2½” | 20 l/h | 130 kg | 915 x 660 x 1100 mm | 30 l |

**When flushed, the mechanical seal is selected